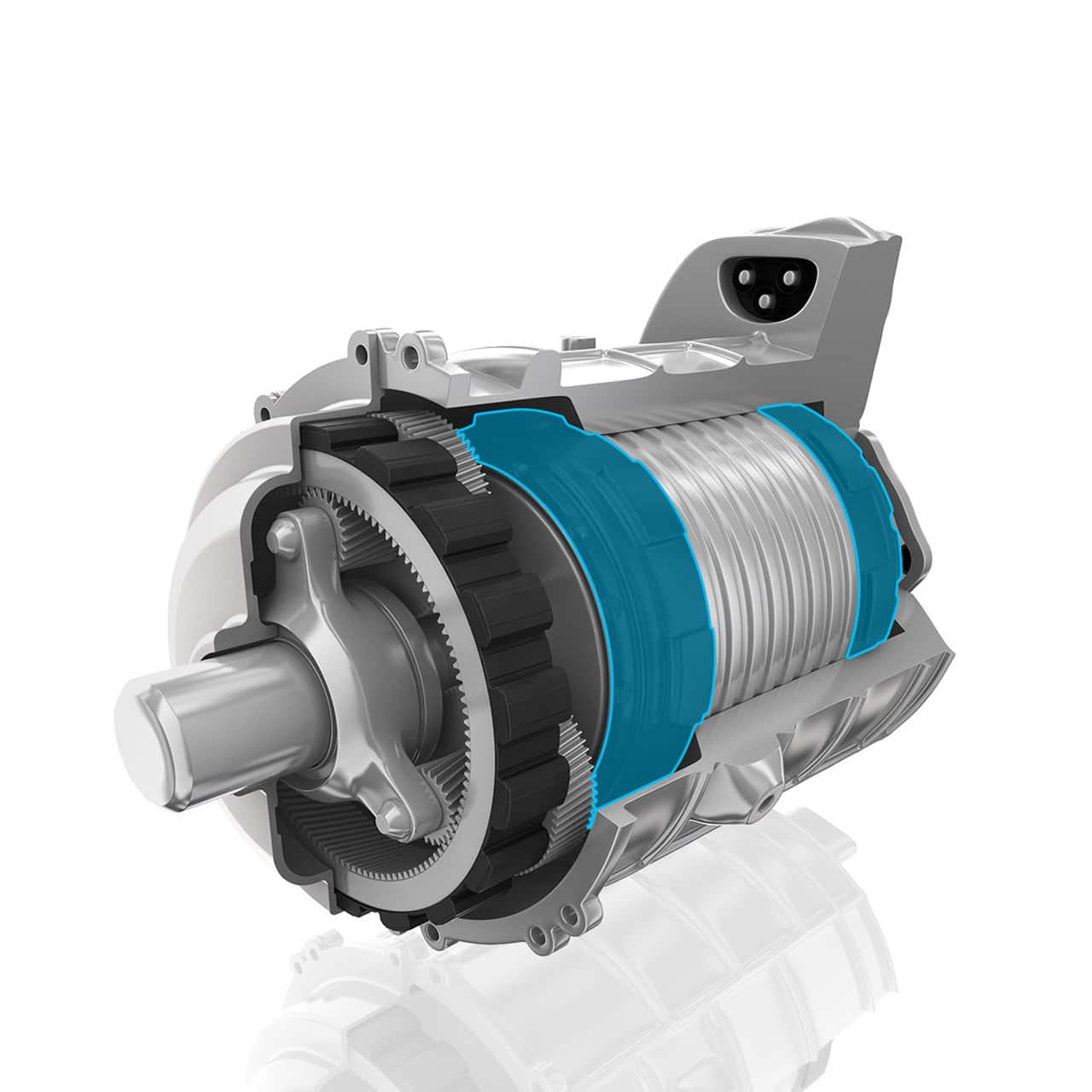

Stator Isolator

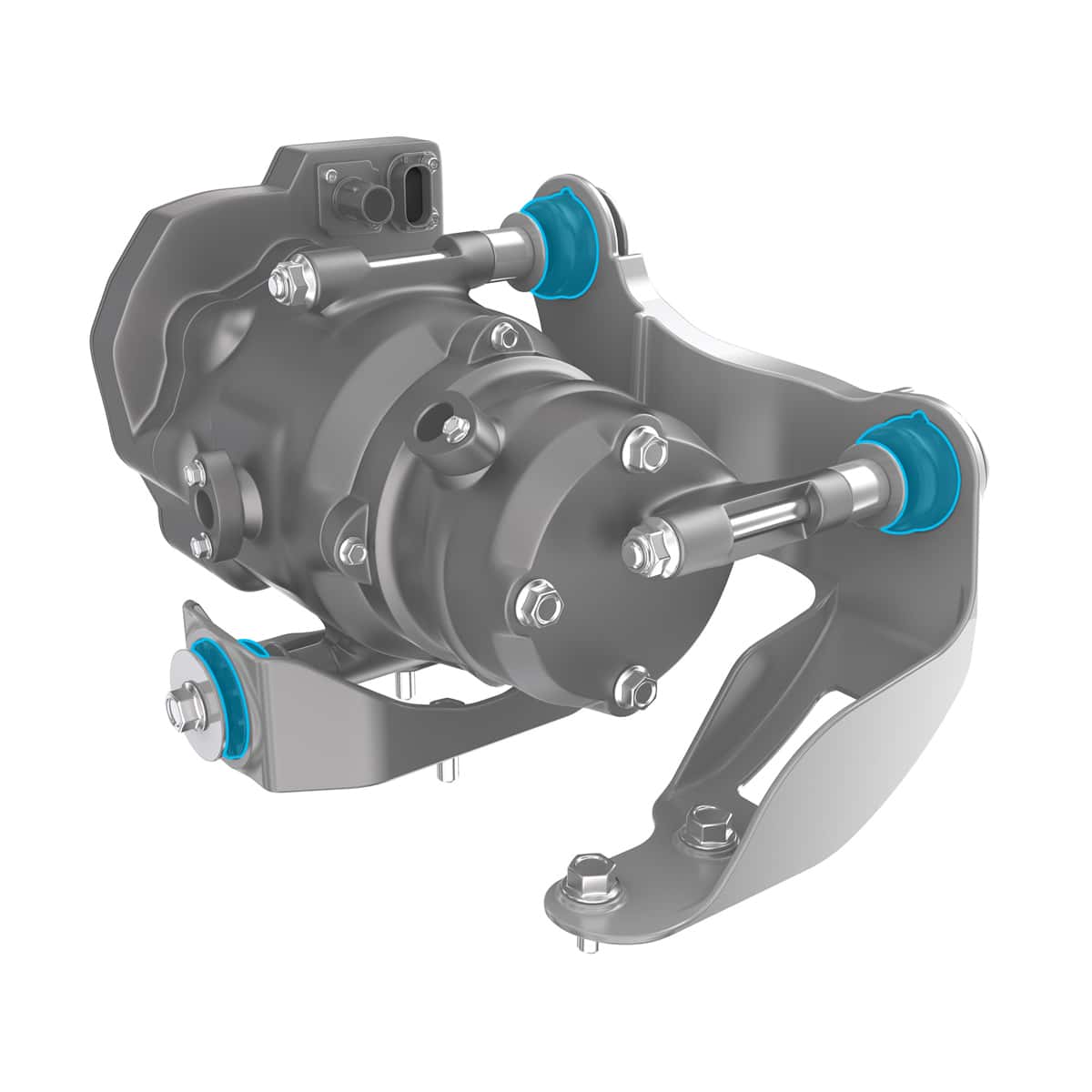

Vibracoustic’s Stator Isolator provides a comprehensive solution to torque ripple effects in e-motors, reducing NVH-related issues and enhancing driver comfort.

Prevents axial, radial, and torsional vibrations

Provides effective seal for circulating oil

Withstands long-term exposure to high-temperature oil

Multifunctional solution for torque ripple in e-motors

Vehicle manufacturers are facing new challenges in electric vehicles NVH management. Vibracoustic’s Stator Isolator offers a unique solution to torque ripple effects caused by fluctuating magnetic fields in e-motors, preventing the transmission of vibrations and enhancing overall vehicle performance.

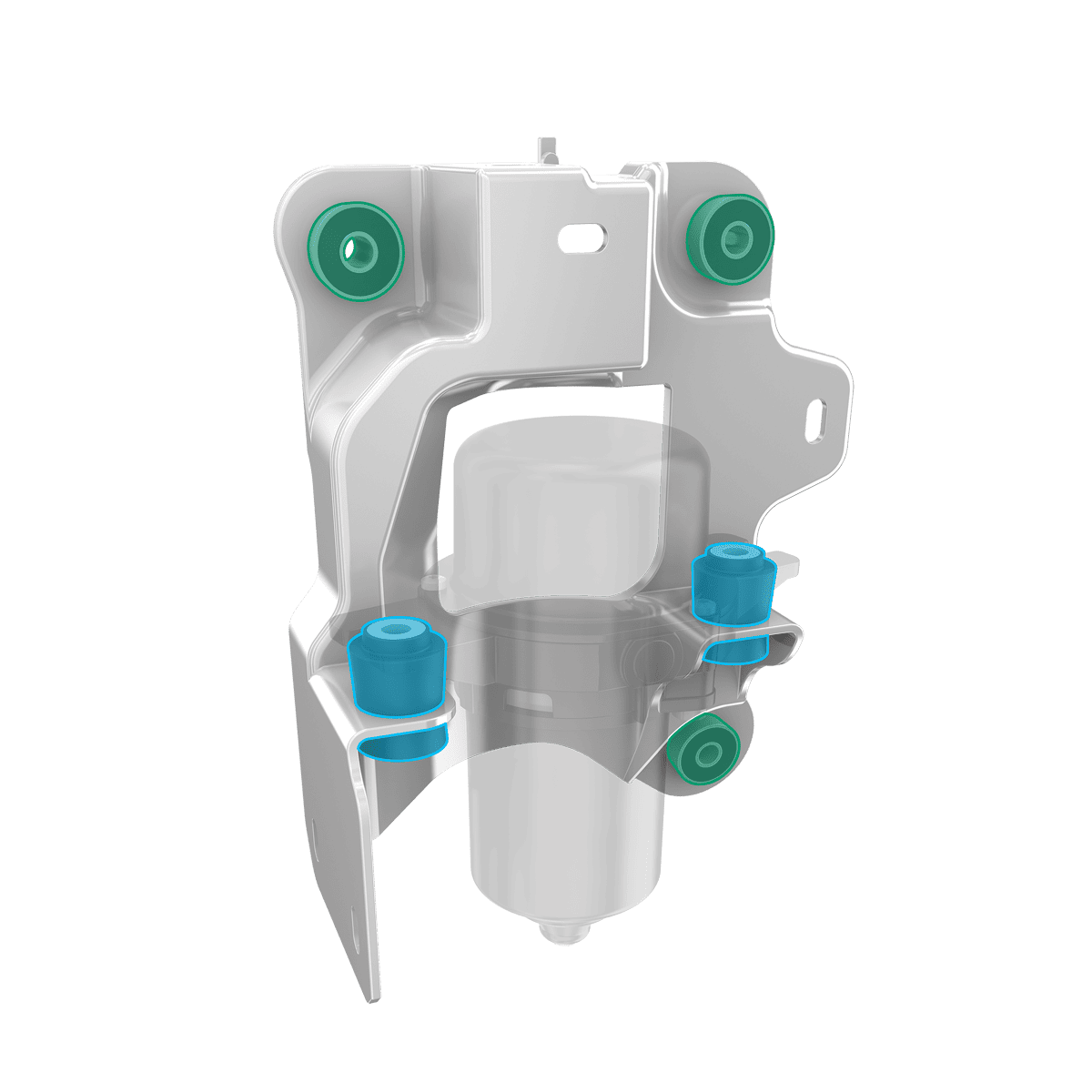

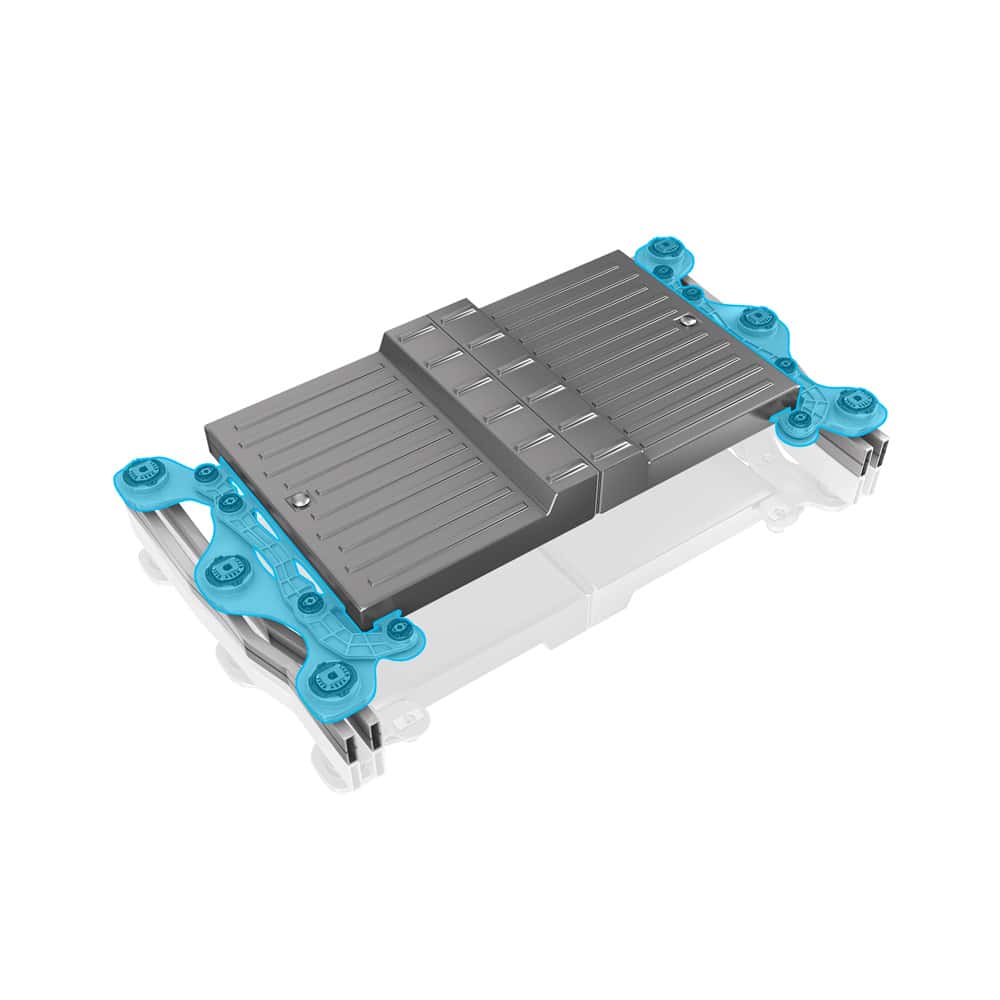

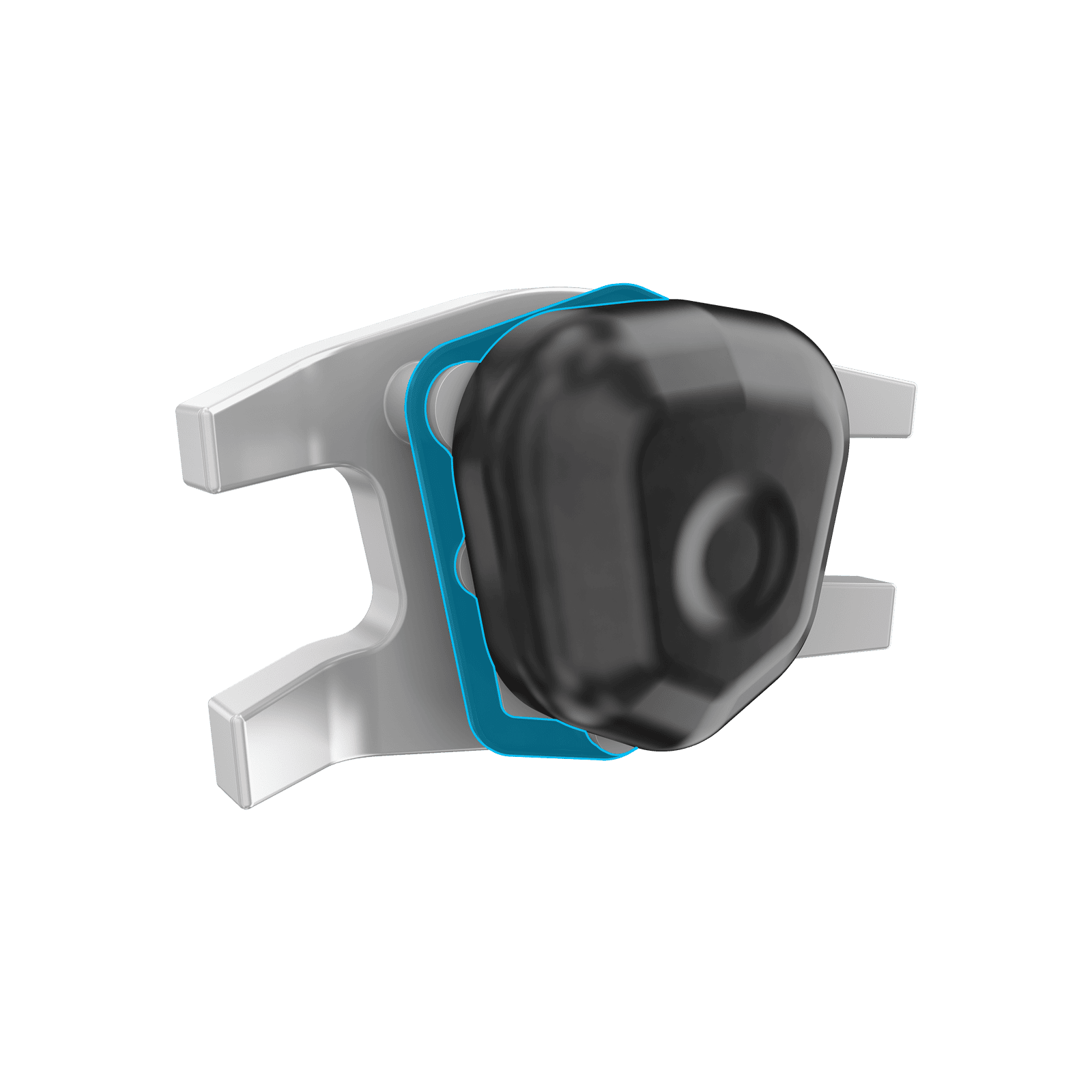

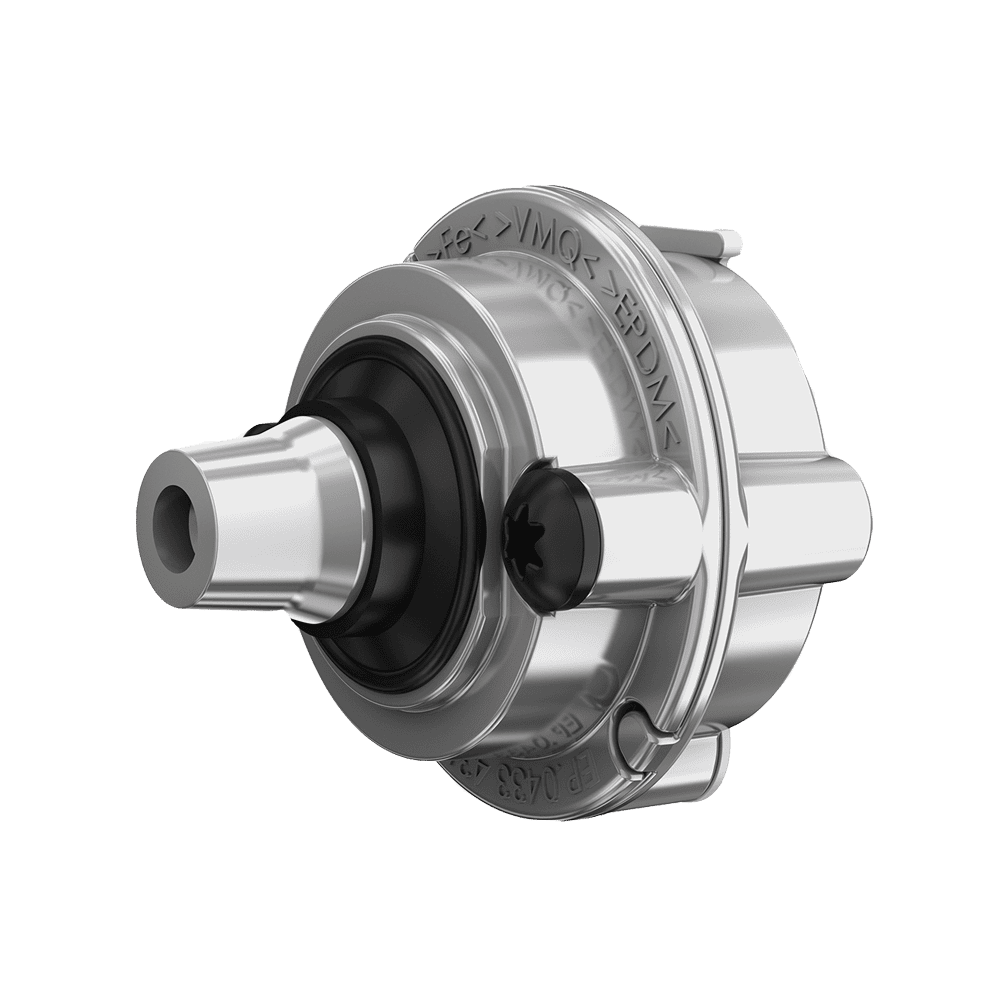

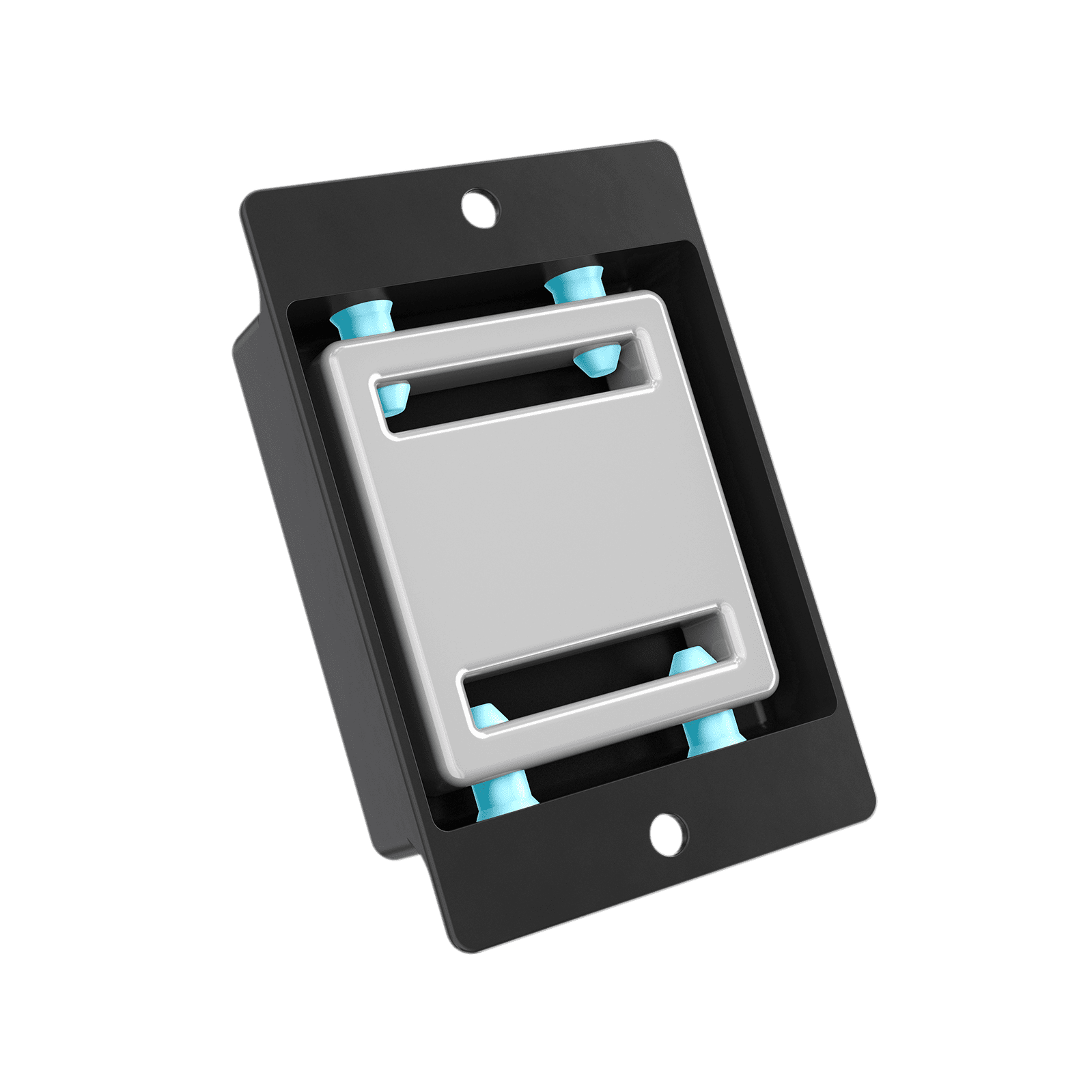

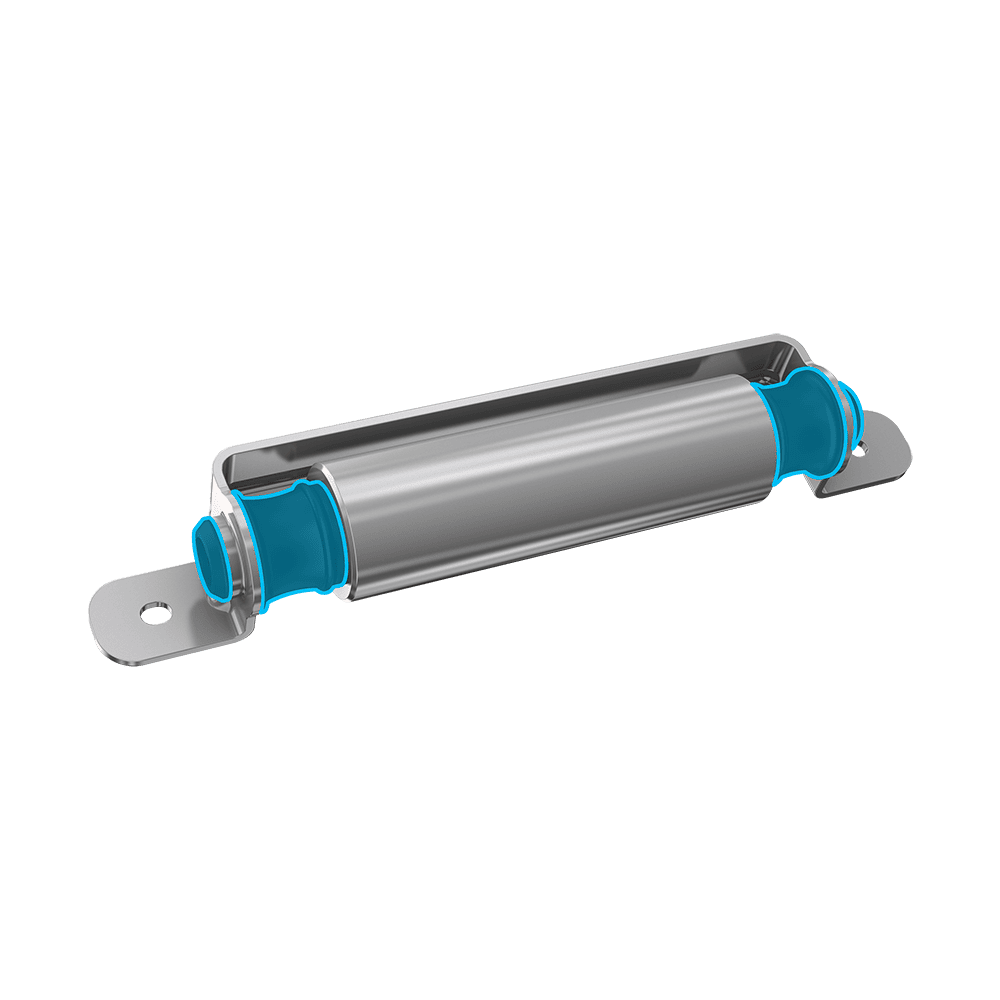

The Stator Isolator is a multifunctional solution designed to prevent the transmission of axial, radial, and torsional vibrations from the stator to its housing, reducing NVH-related issues such as unwanted radiation of airborne noises. Integrated with e-motor cooling devices, the Stator Isolator also provides an effective seal for circulating oil, essential for e-motor durability and safe operation. Developed using Vibracoustic’s expertise in rubber compounds, the Stator Isolator is designed to withstand long-term exposure to high-temperature oil while maintaining tight tolerances.

The product is designed to be adapted to the existing stator carrier, with unique form-fit geometries that prevent rotation and provide an effective and durable seal.

Initially intended for premium segment vehicles where NVH management is paramount, the Stator Isolator can be integrated into any vehicle using e-motors, offering a comprehensive solution to torque ripple effects and enhancing overall NVH performance.