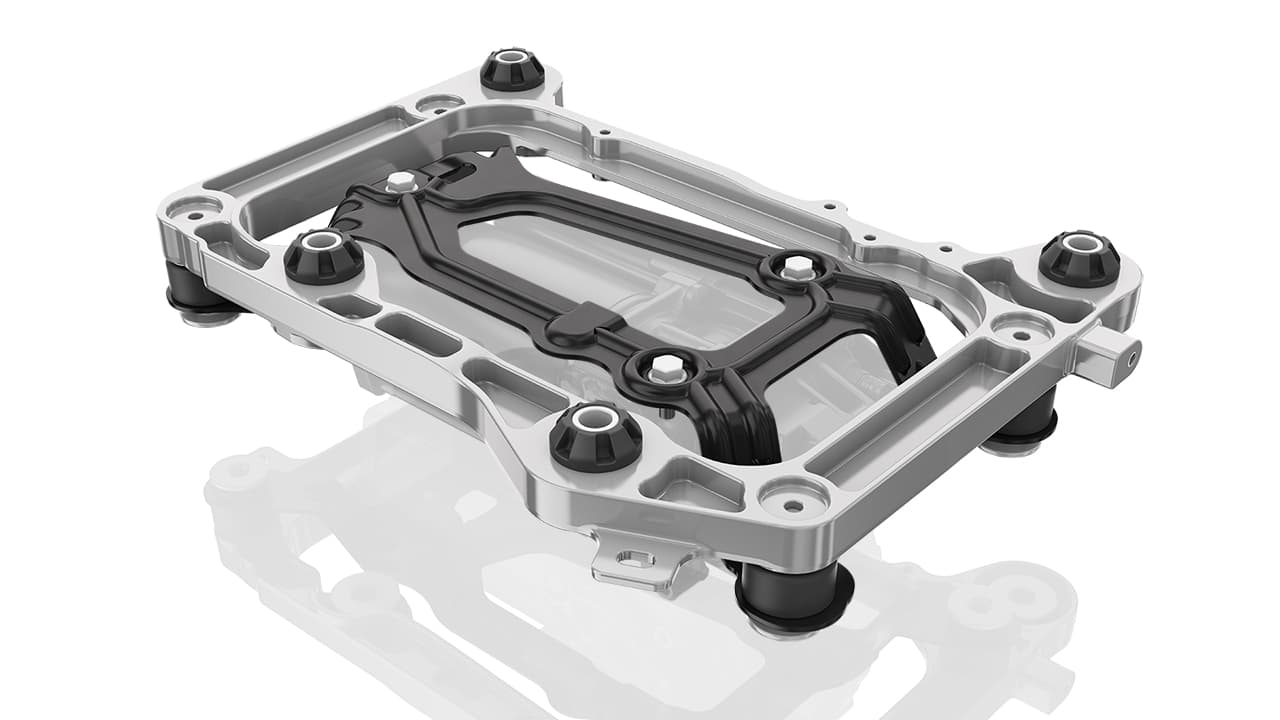

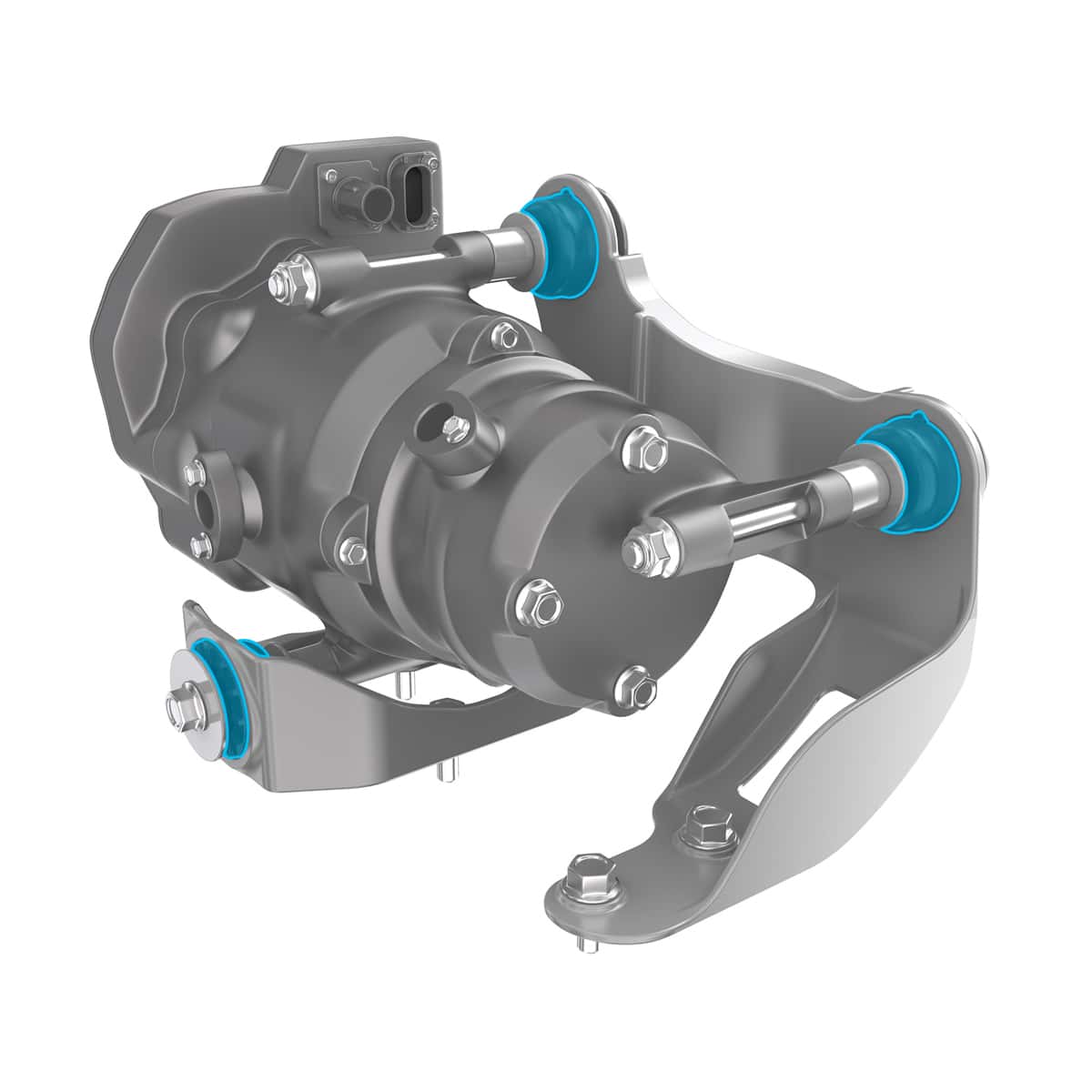

Air Supply Unit Bracket

The air supply units (ASUs) bracket is a tunable solution that improves NVH performance through radial and axial damping. It provides reduced weight and complexity and reduces the resonance caused by the compressor excitations.

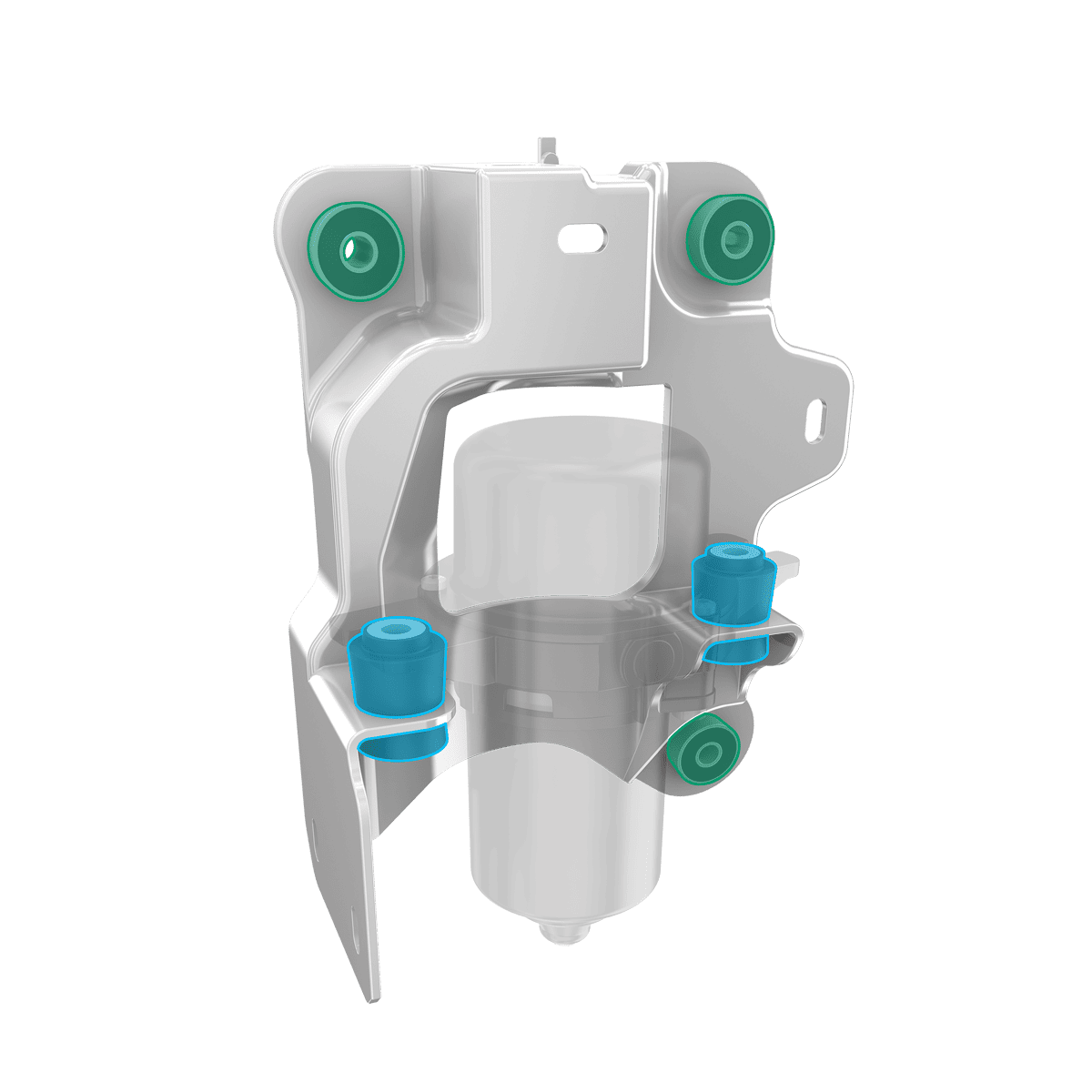

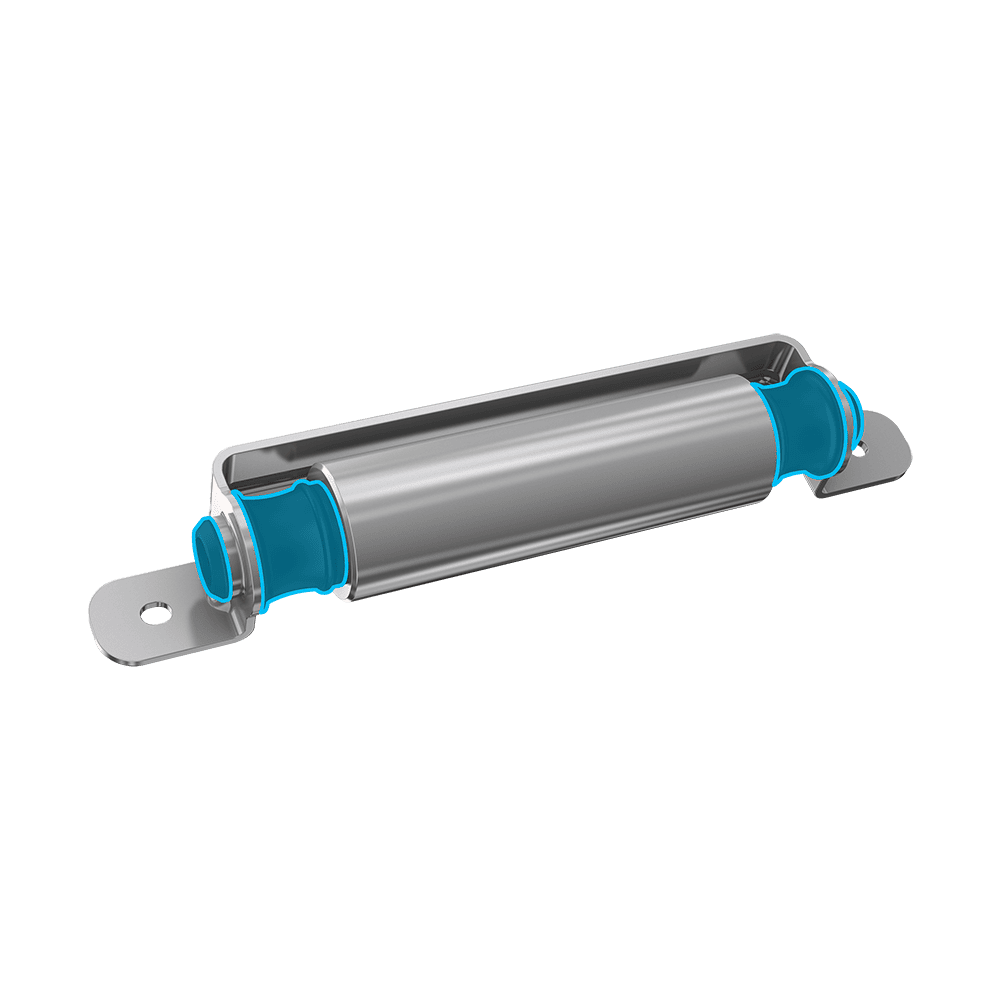

radial and axial damping

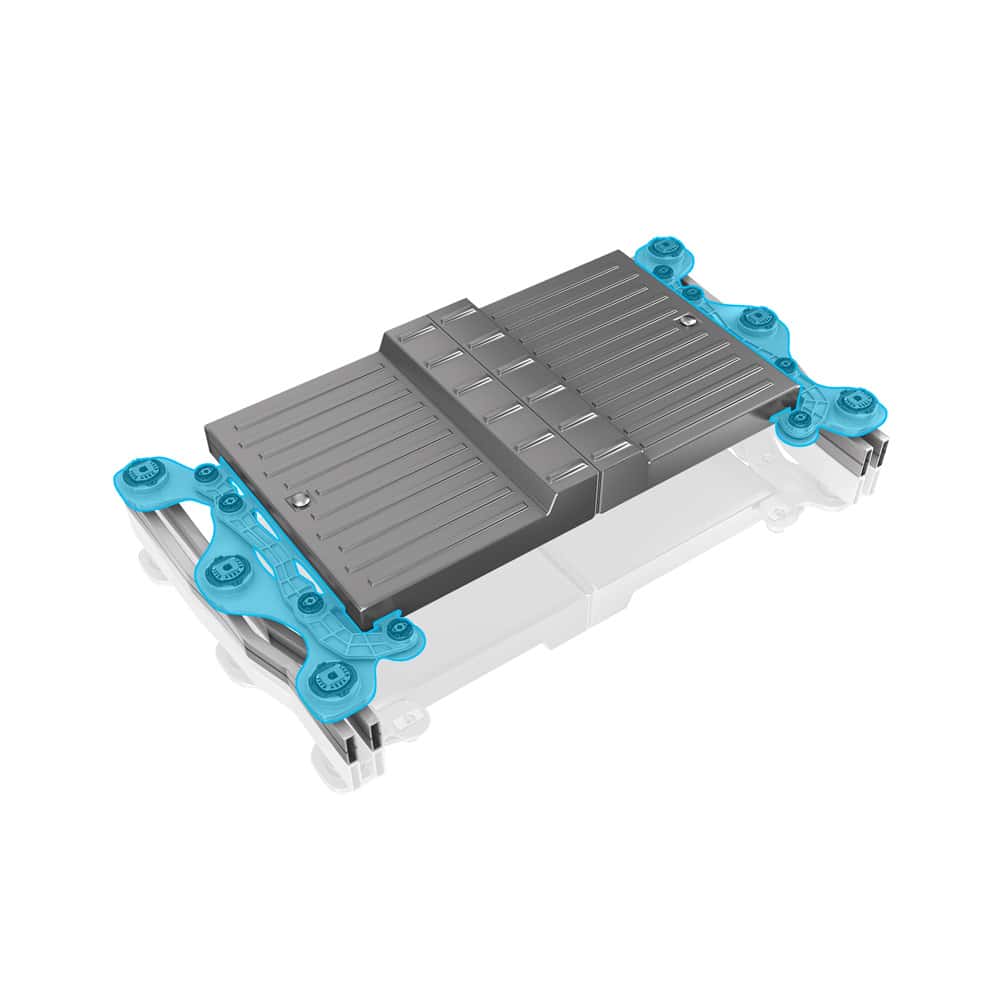

reduced dynamic stiffness peak

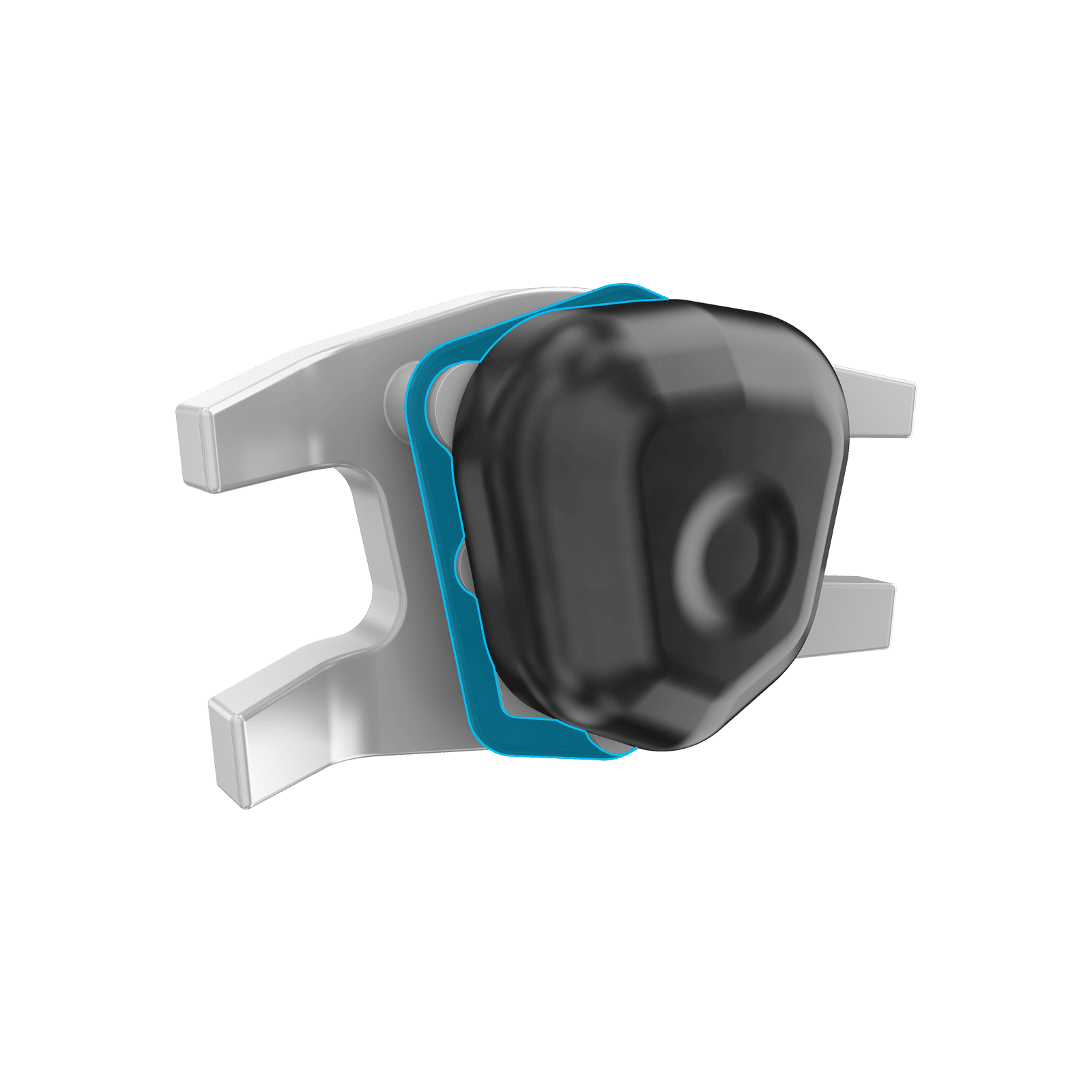

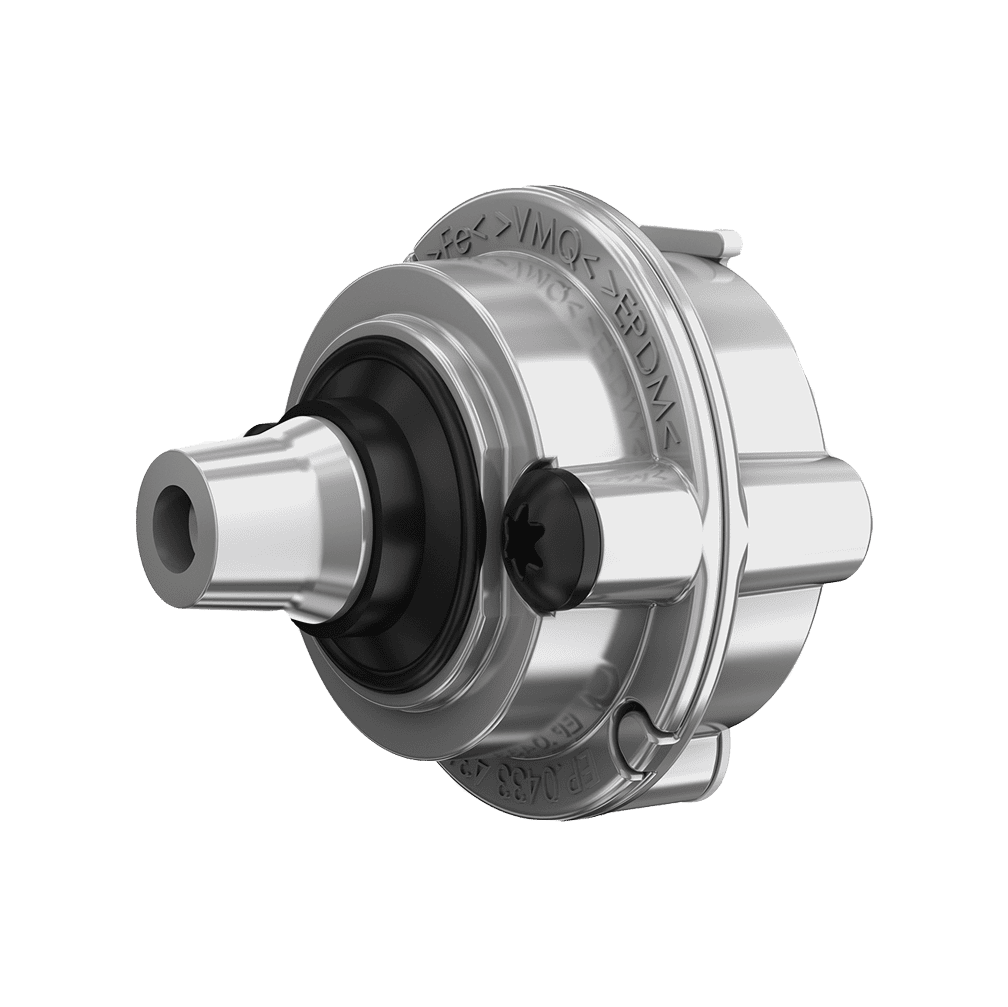

“roll over” bellow design

The air supply unit (ASU) is part of the complete air spring system and carries the compressor as well as the valve block. Vibracoustic ASU mounting bracket allows for NVH tuning in all directions, including radial and axial damping, something not possible with the coil springs typically used in such applications.

The greater consumer demand for comfort calls for more advanced air spring systems. To address the downsides of coil springs in bracket applications – their high resonance responses and the inability to provide a tunable support for radial deflections and excitations – Vibracoustic engineers created an alternative rubber mounting system including bellow-style bushings and bump stops. Thanks to the compound used the solution reaches required stiffness levels while damping both radial and axial excitations. The ‘roll-over’ bellow design allows for high displacement at low strain levels, mimicking the performance of springs.

The rubber compound demonstrates a dynamic stiffness peak that is up to 60 per cent lower than solutions with a coil spring which provides a further benefit for the NVH performance.

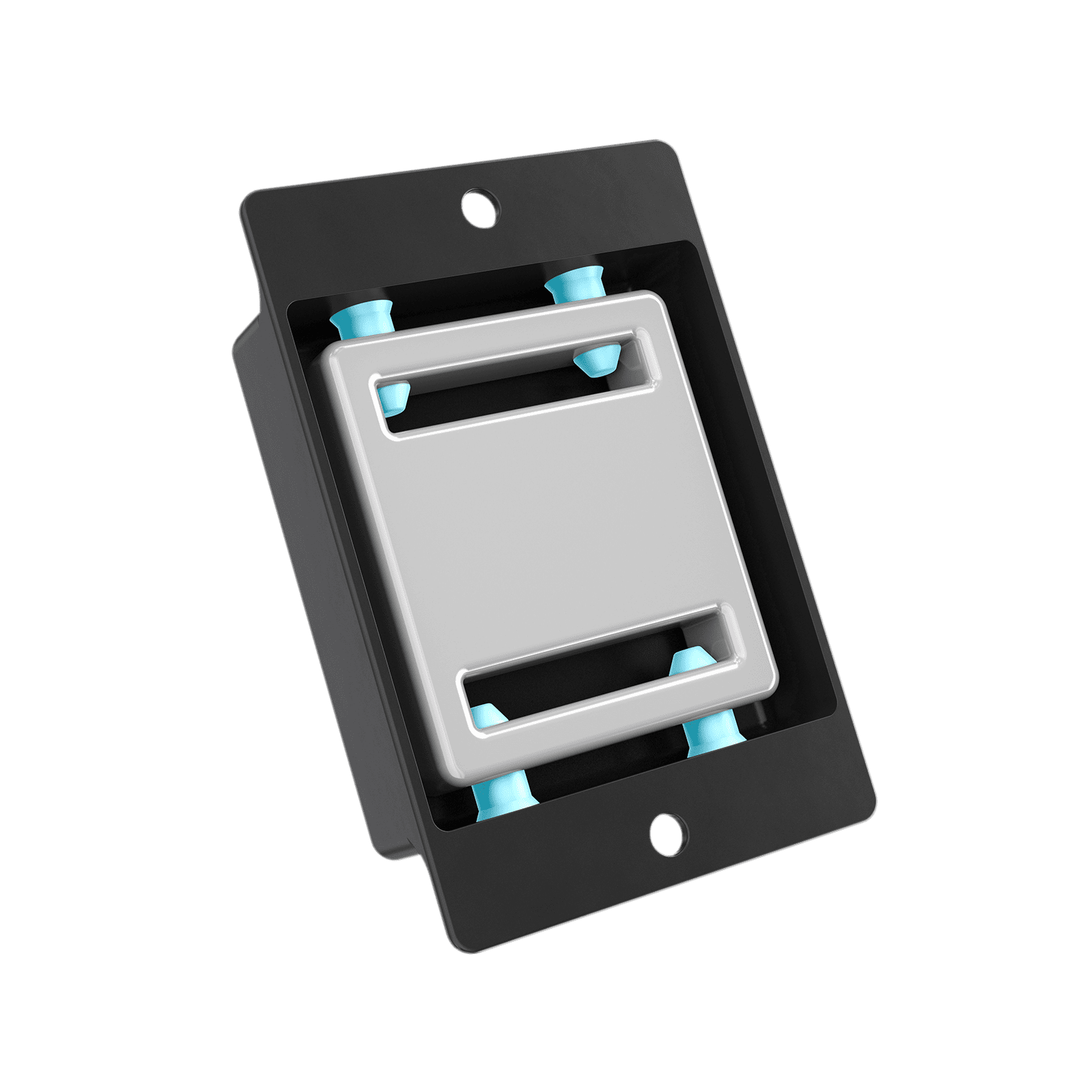

Furthermore, a snap-fit connection secures ease of assembly for OEMs. The team also improved the bracket itself, switching from metal to plastic. This provides damping to further improve system NVH and eliminate aggressive resonance while also leading to weight savings.