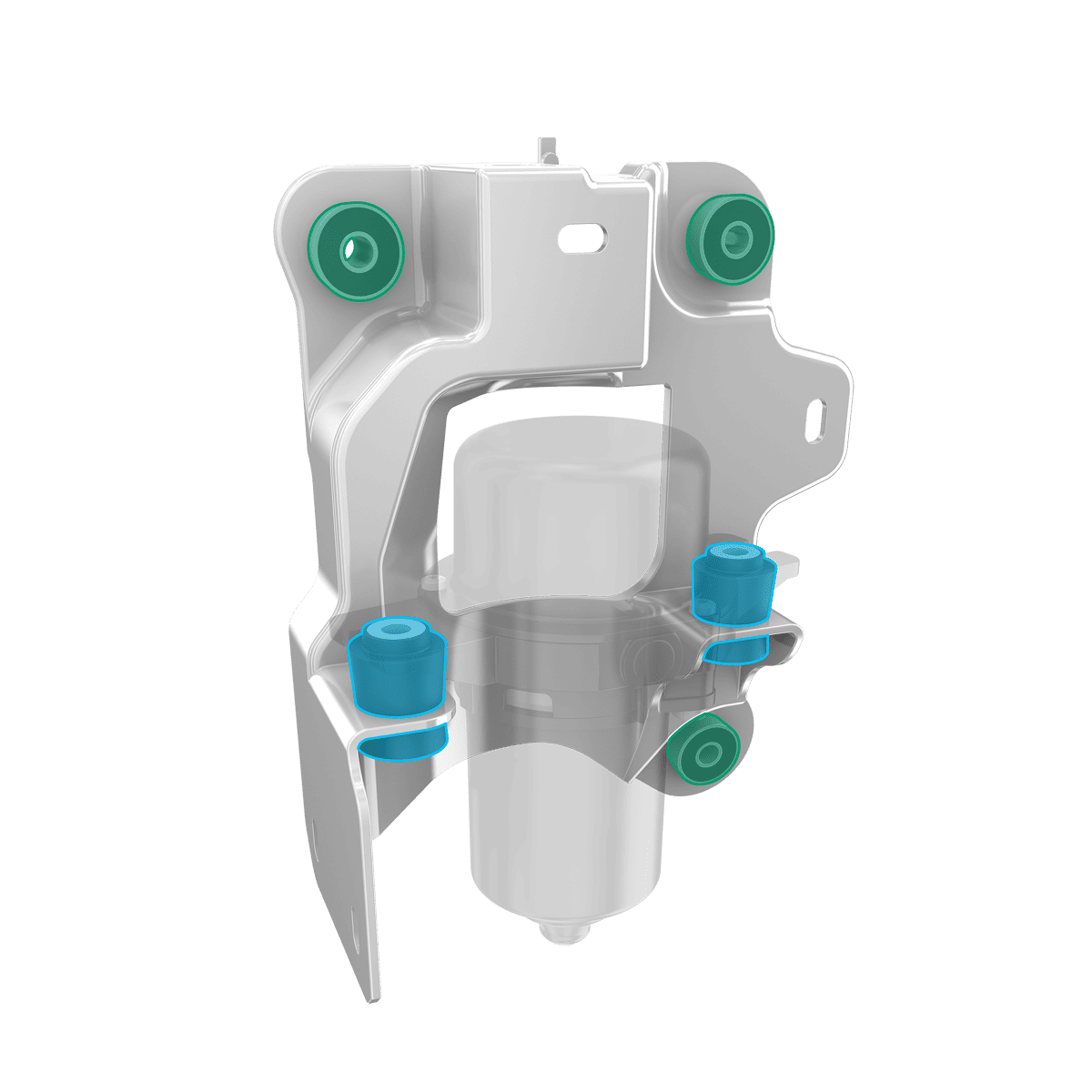

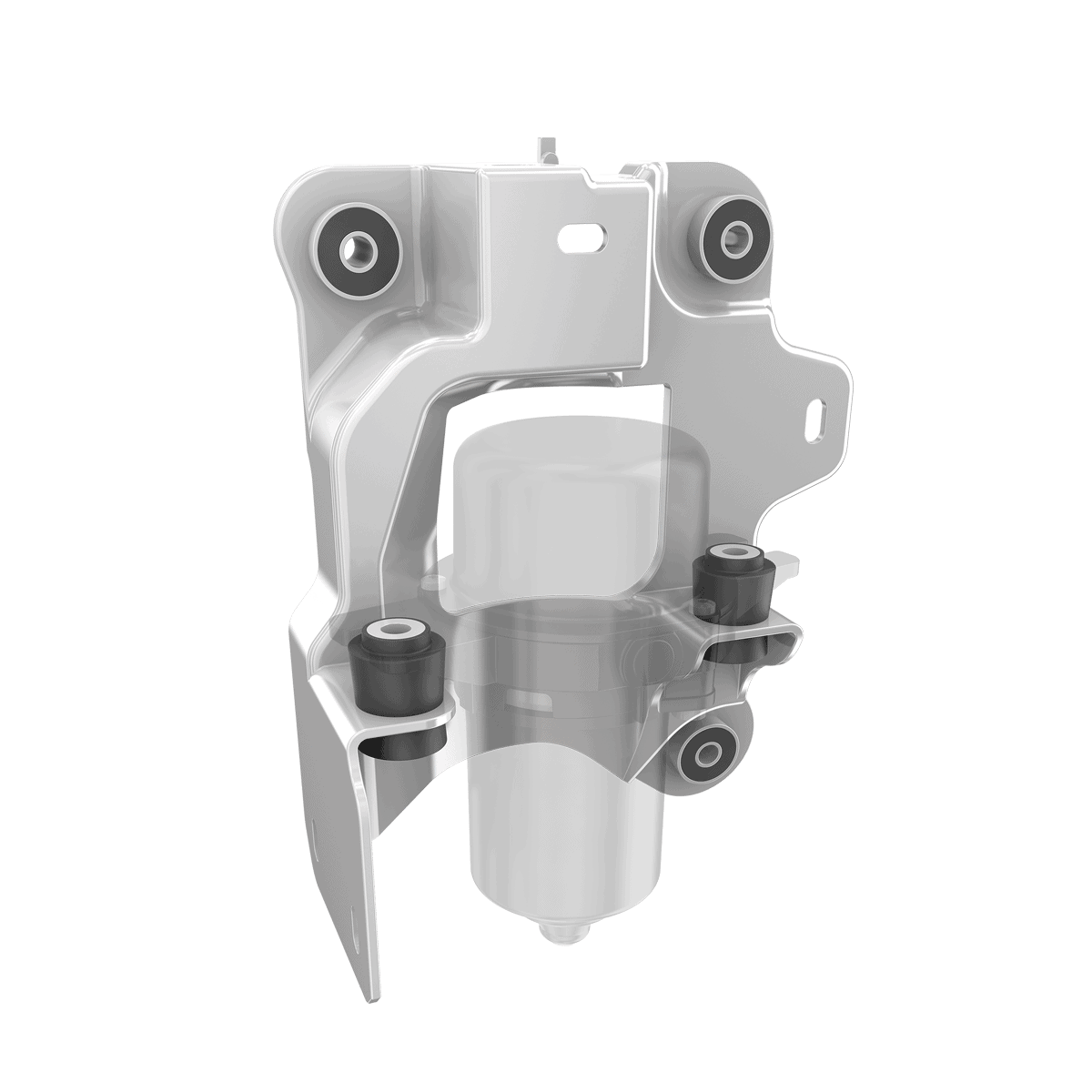

Vacuum Pump Decoupling

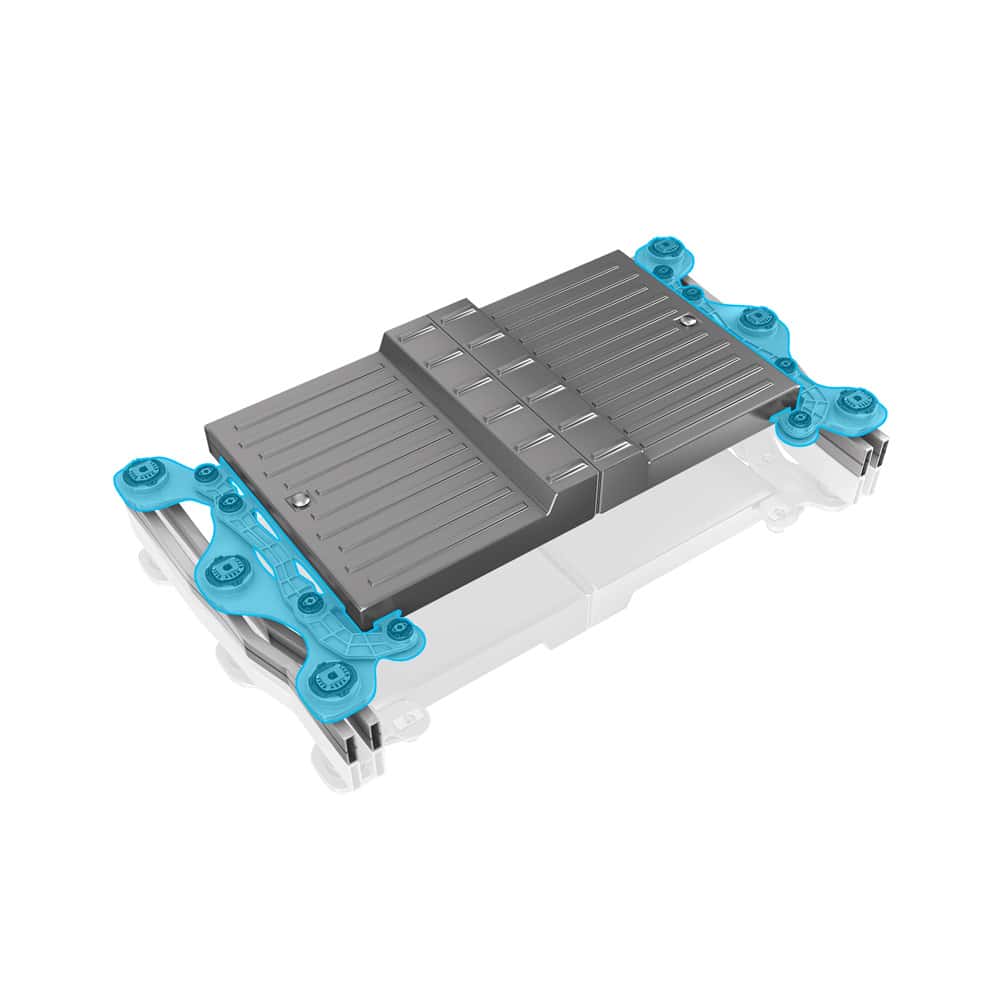

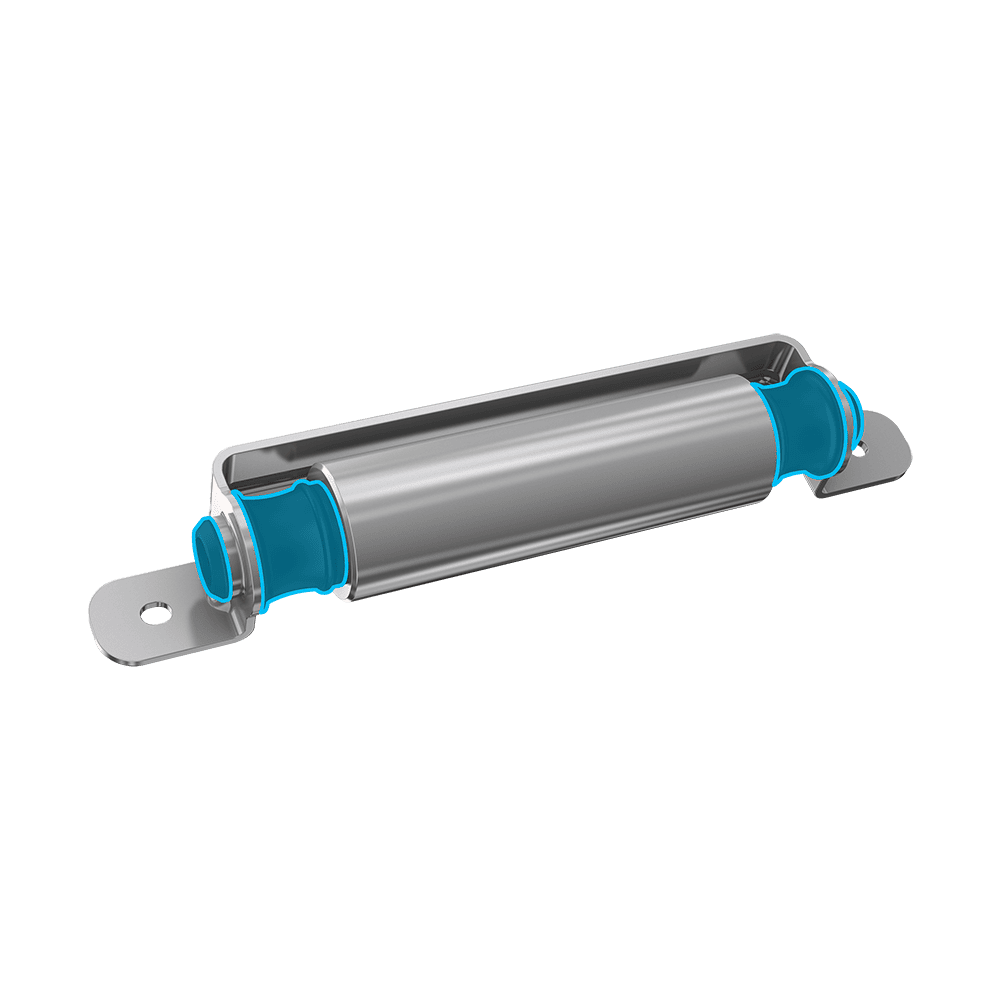

Decoupling systems for auxiliary components like coolers, pumps and compressors eliminate unwanted noises.

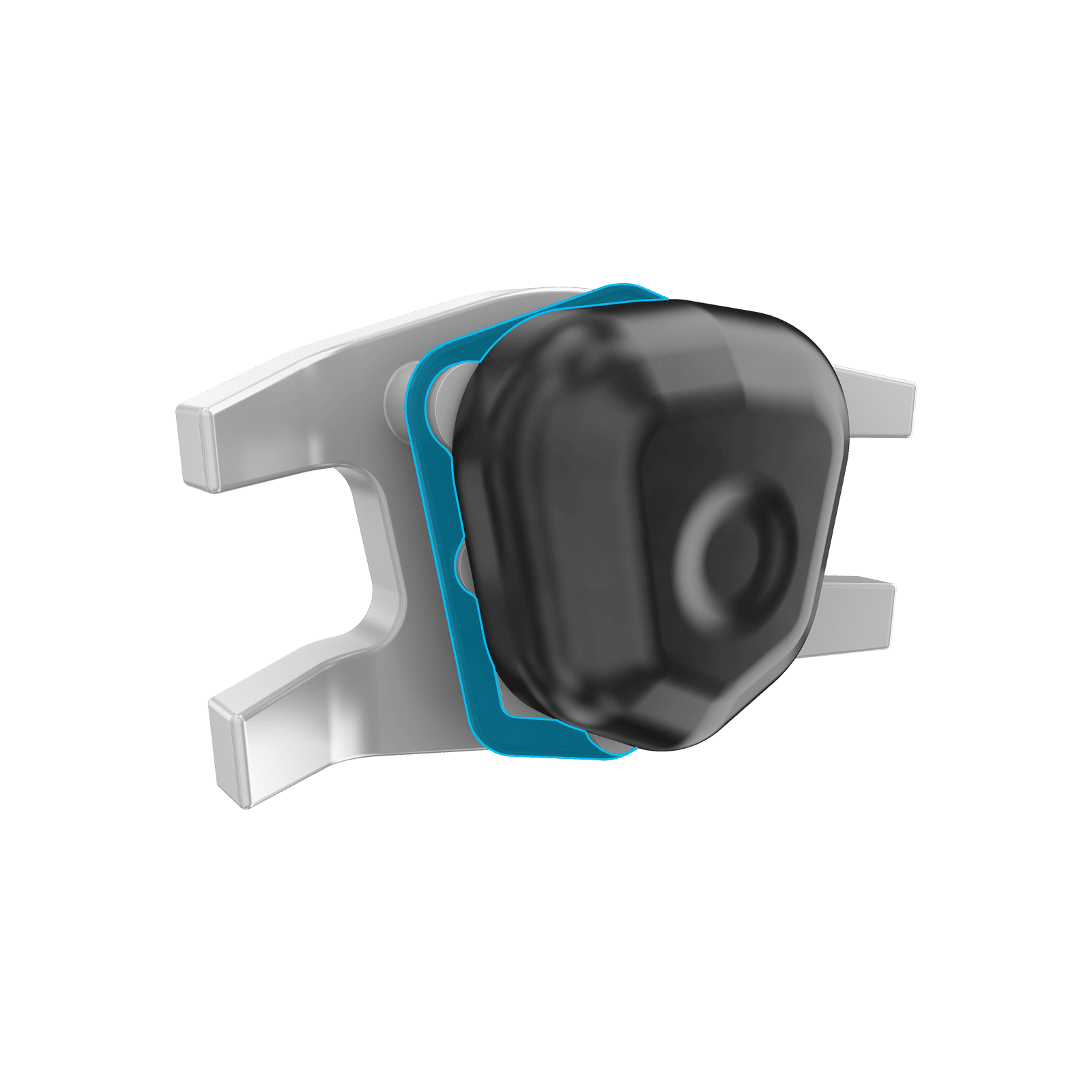

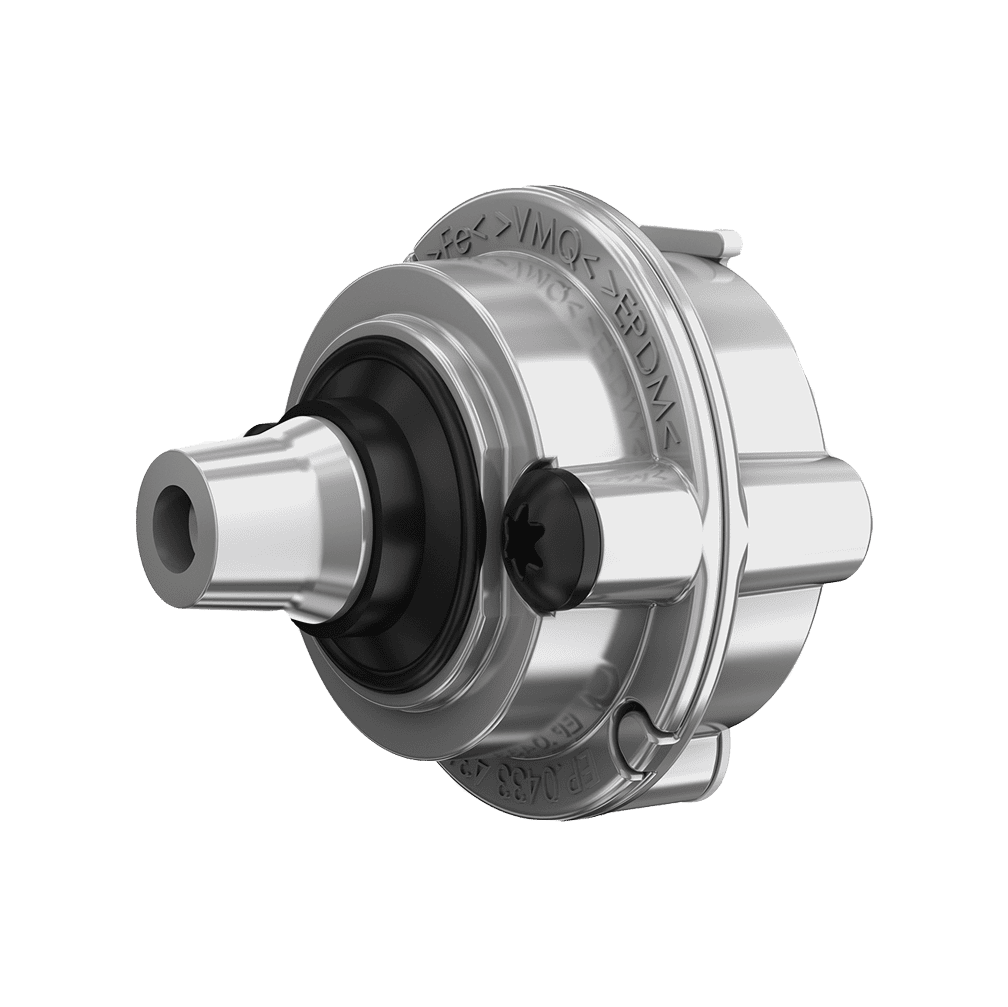

Low stiffness with special rubber shapes with integrated travel-limiters possible

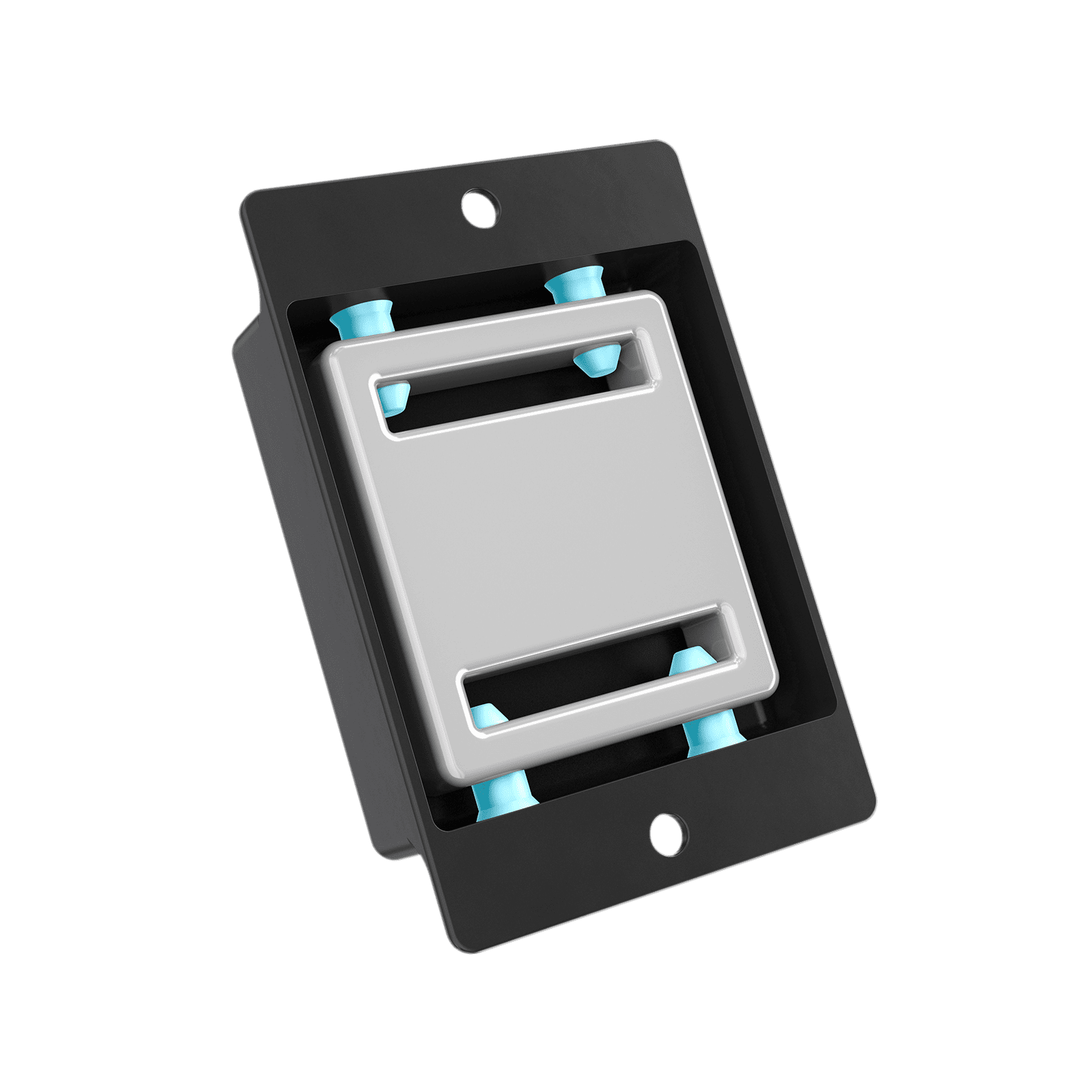

Wide range of decoupling solutions for auxiliary components

System know-how for best integration into vehicle architecture

Single and dual layer isolation concepts possible

Electric vehicles may no longer use internal combustion engines, but they still require various auxiliary systems like cooling for batteries, motors and the cabin or to support the braking system. As auxiliary systems – like coolers, pumps and compressors – are not belt-driven in e-mobility applications any more, automotive manufacturers are facing a range of new NVH challenges.

Decoupling of these systems has become an increasingly important focus for vehicle manufacturers, as the noise and vibration that they generate is no longer masked by the internal combustion engine. In addition, these auxiliary systems are no longer positionally constrained by the location of the engine, meaning that they could be packaged differently within the chassis, leading to a host of new NVH issues.

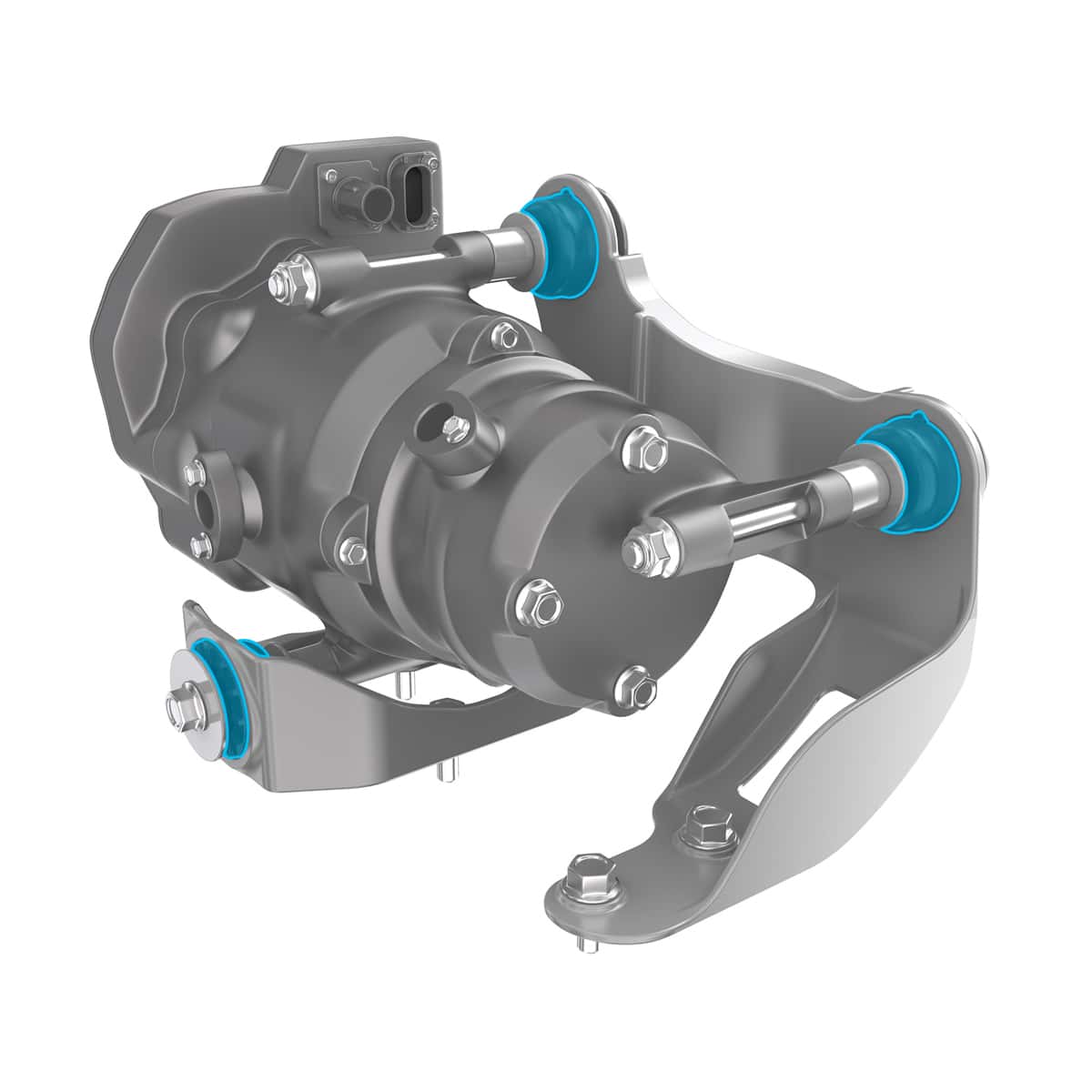

These decoupling solutions take into account wider vehicle NVH considerations and include the option for single or double isolation layers. A double isolated bracket was used for a vacuum pump for the braking system of a standard C-segment vehicle to eliminate unwanted noises of the braking system. While these NVH issues had no impact on the performance of the vehicle’s braking system, many customers would perceive this as a safety-critical issue or attribute it to poor build quality.