Steering Dampers

Mitigate driver disturbance and fatigue while improving comfort.

High-quality materials and construction for high durability

Can be tuned and optimized for multiple directions and excitations

Highly durable temperature-independent REQILL dampers

Steering wheel vibrations can disturb drivers, giving them the impression that something is wrong, even when that is not the case. Often transmitted from bending modes in the steering column and caused by motor, auxiliary or road surface excitations, steering vibrations can increase driver fatigue and negatively affect a driver’s perception of quality and safety. Vibracoustic works with customers to develop bespoke solutions that help to manage and mitigate these detrimental NVH characteristics. Using high-quality materials and innovative engineering design, Vibracoustic’s solutions are tuned to each application and can be modified to meet specific assembly requirements.

Vibracoustic offers different steering damper solutions, each customizable to suit customer applications and NVH optimization goals:

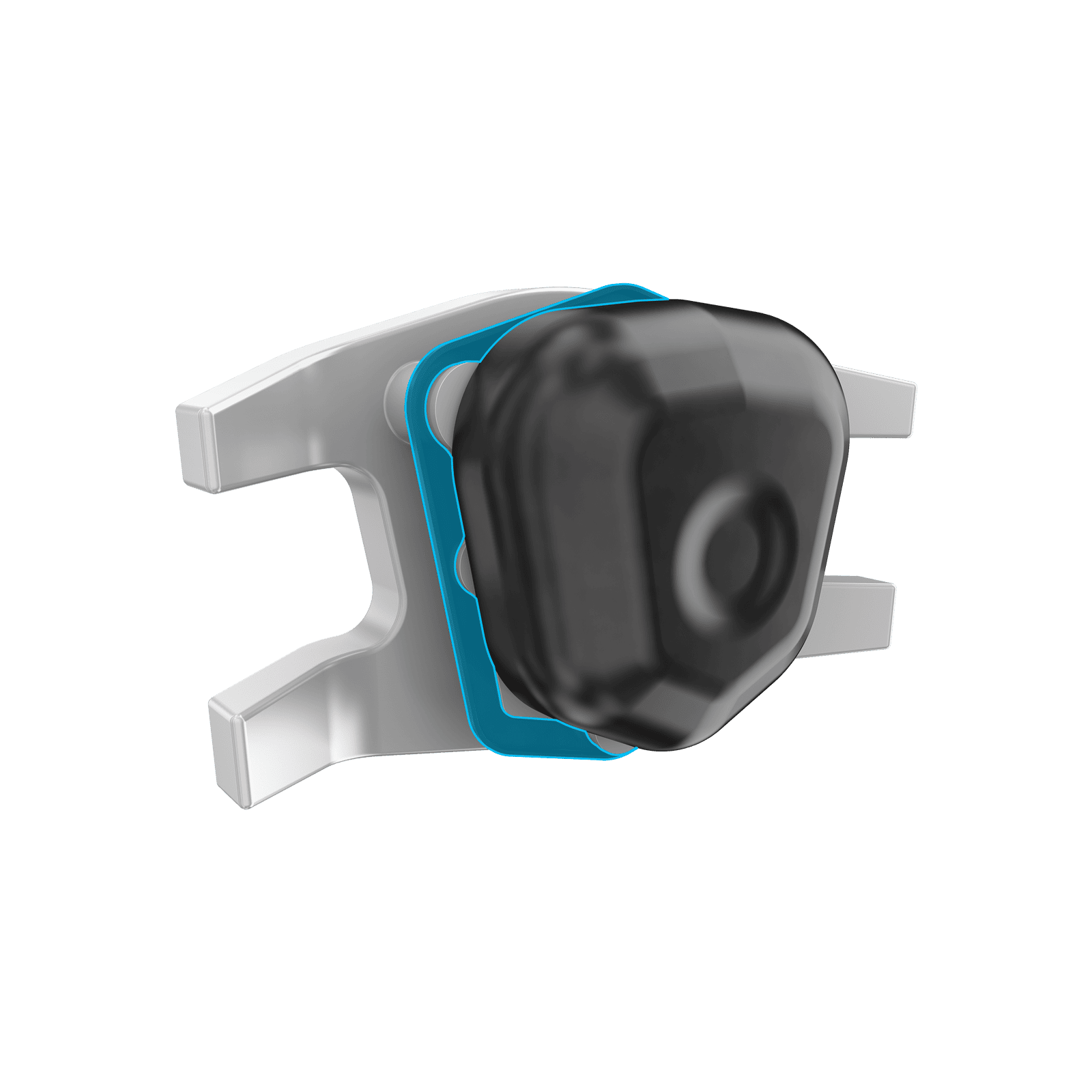

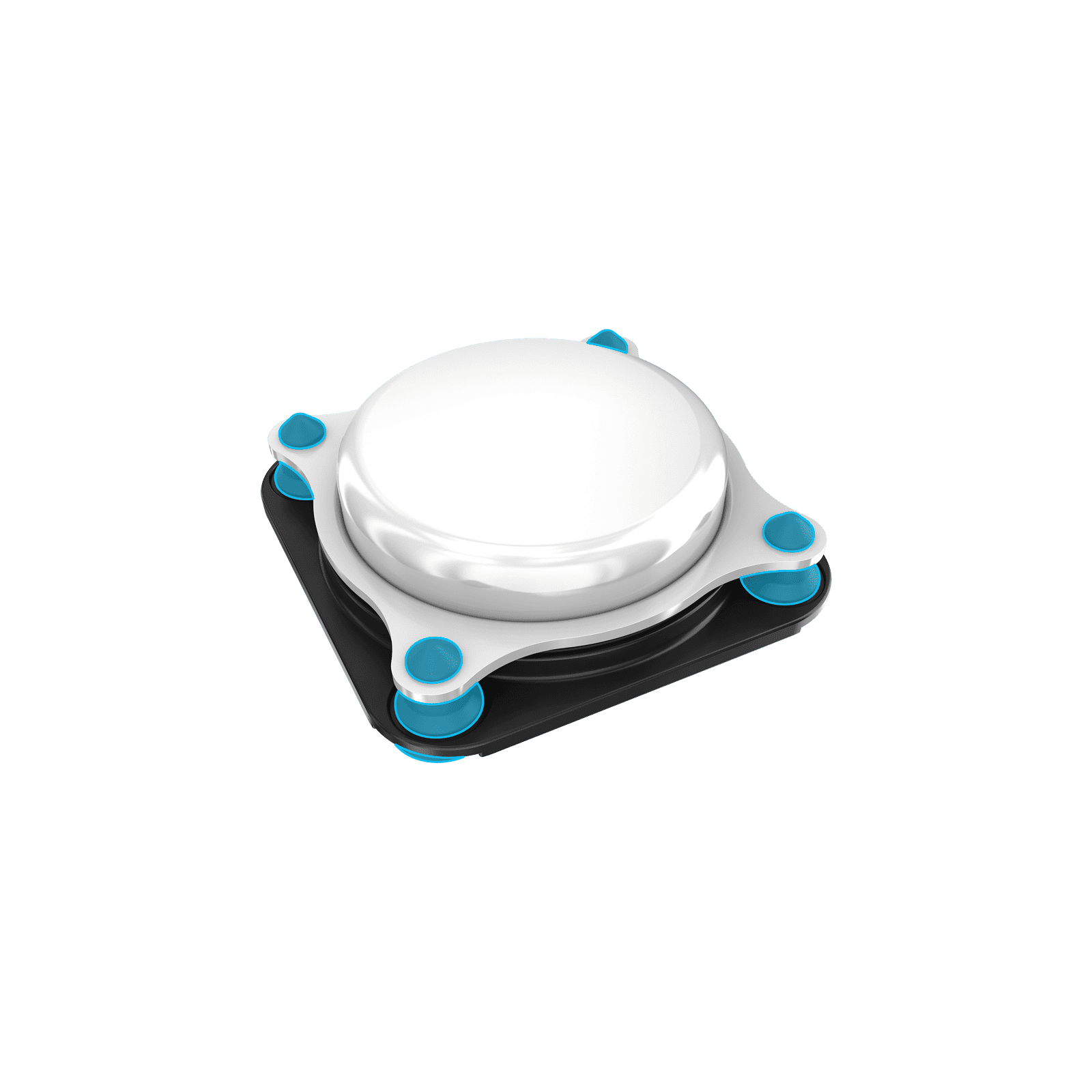

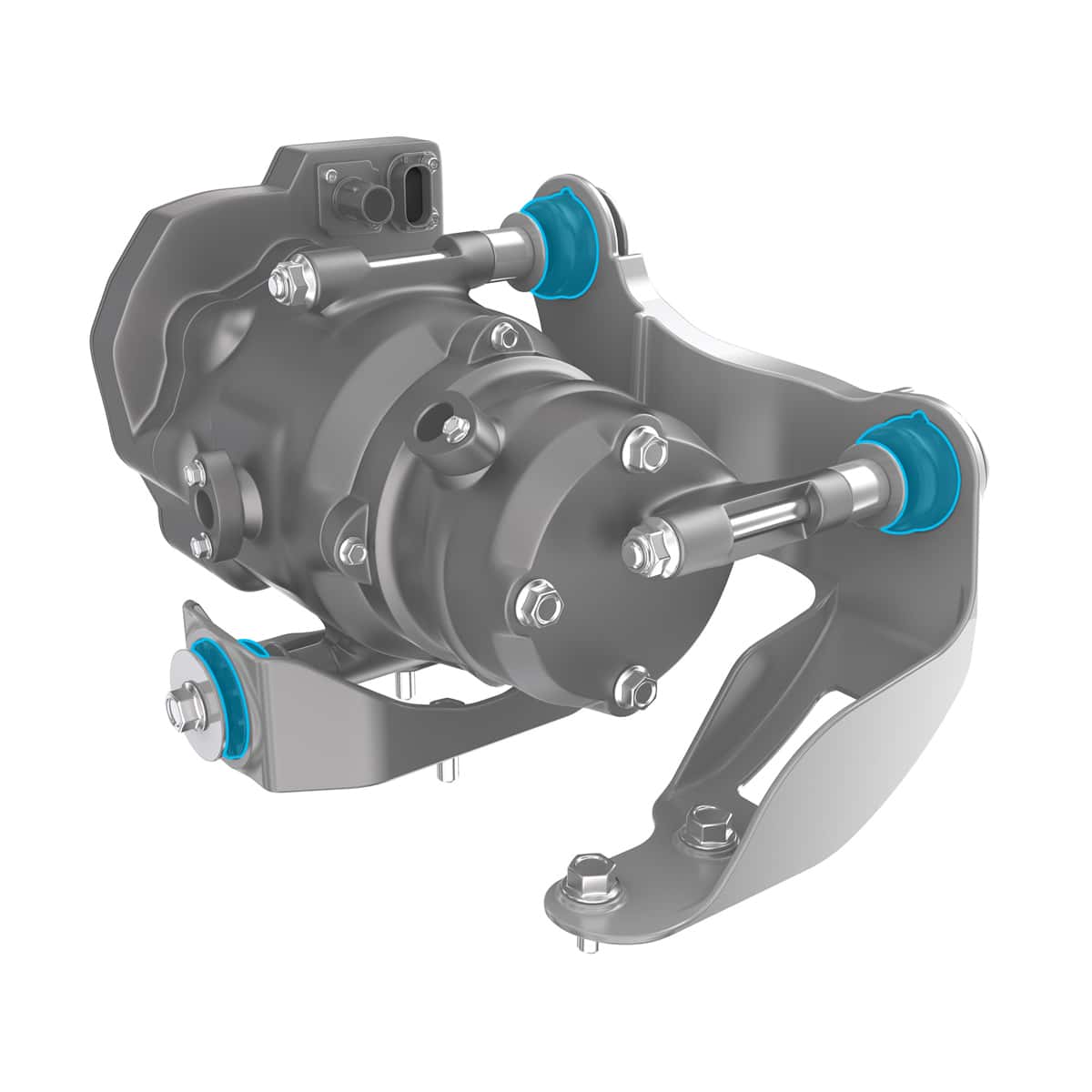

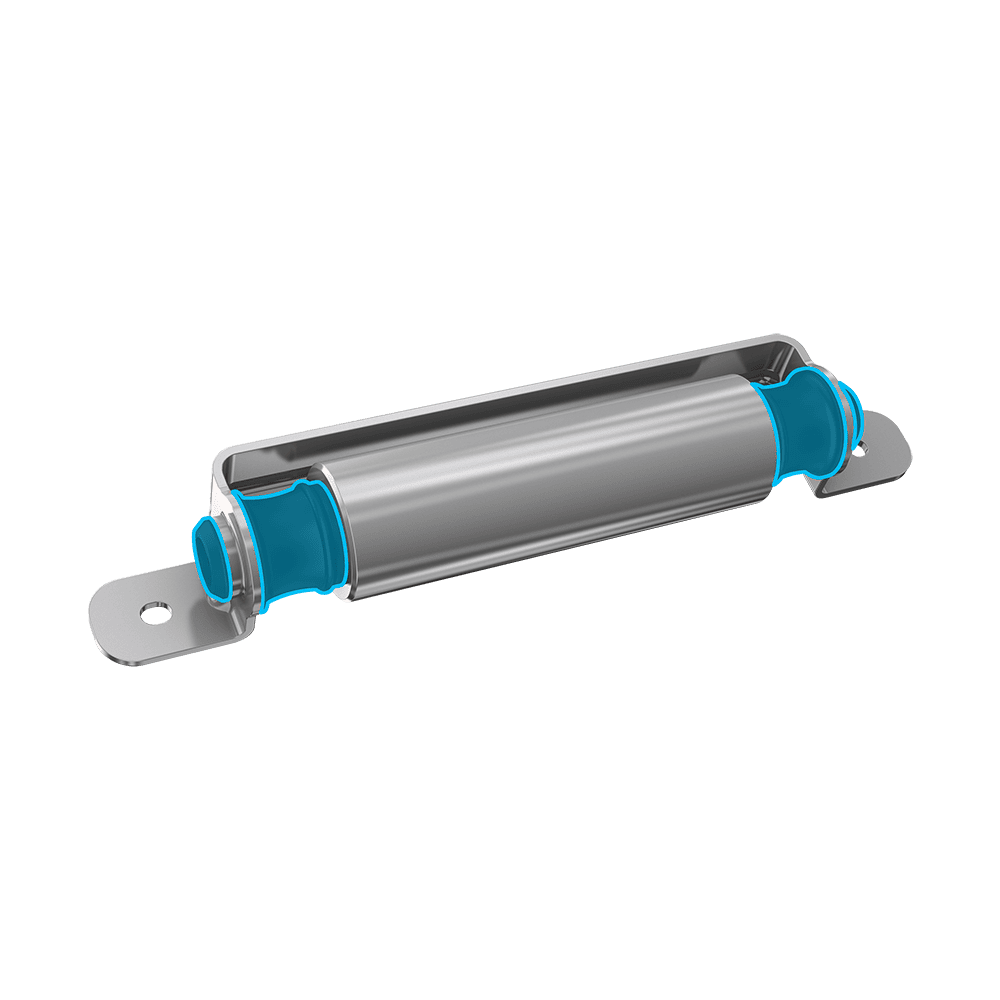

Steering Wheel Damper (with or without bracket)

This solution uses a tuned die-cast zinc mass mounted with cone-shaped silicone rubber dampers to counter and dampen vibrations in the steering wheel. These can be tuned to mitigate vibrations in multiple directions. The steering wheel damper can also be mounted via a sheet metal bracket to the steering wheel armature. Elastomer limiters prevent excessive movement of the mass.

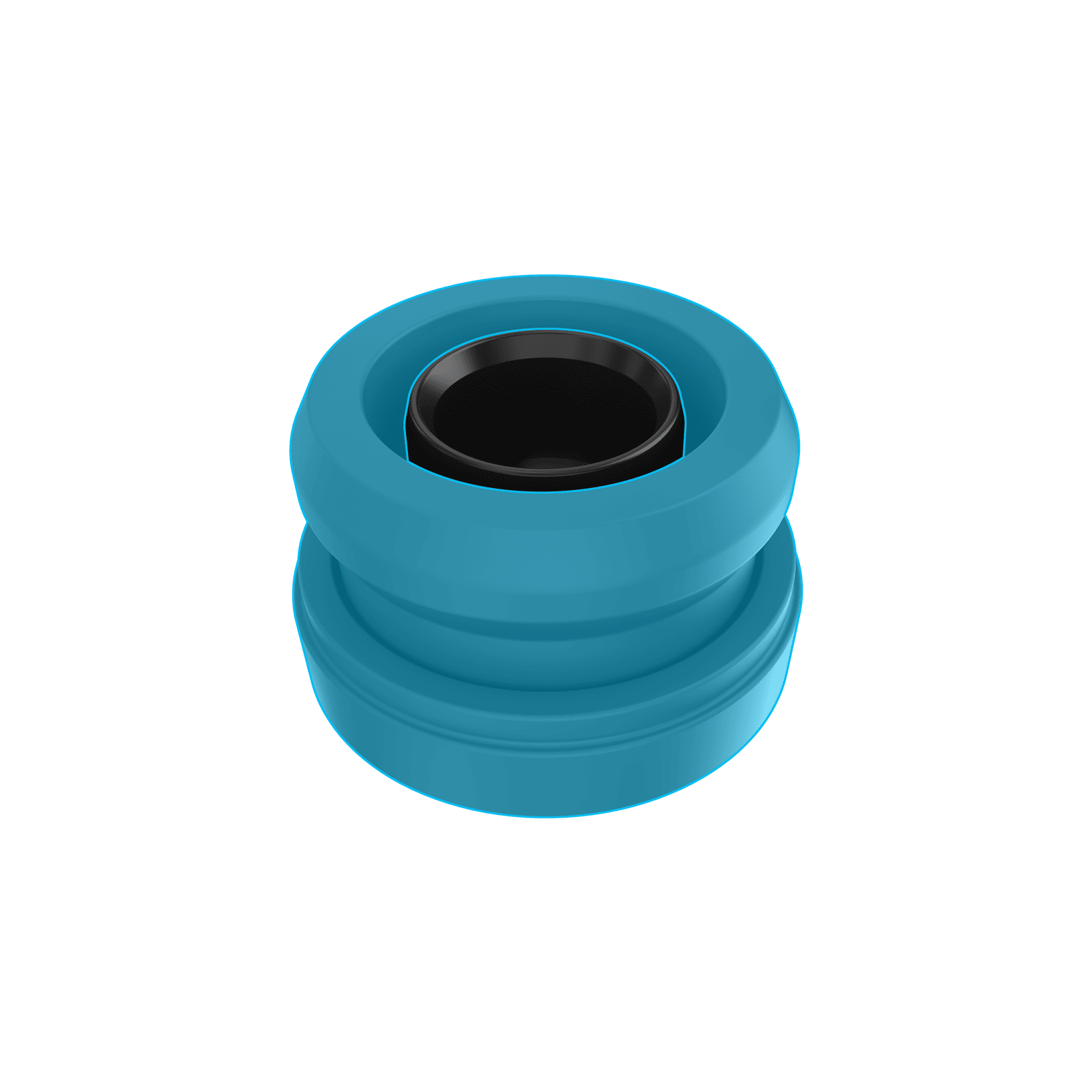

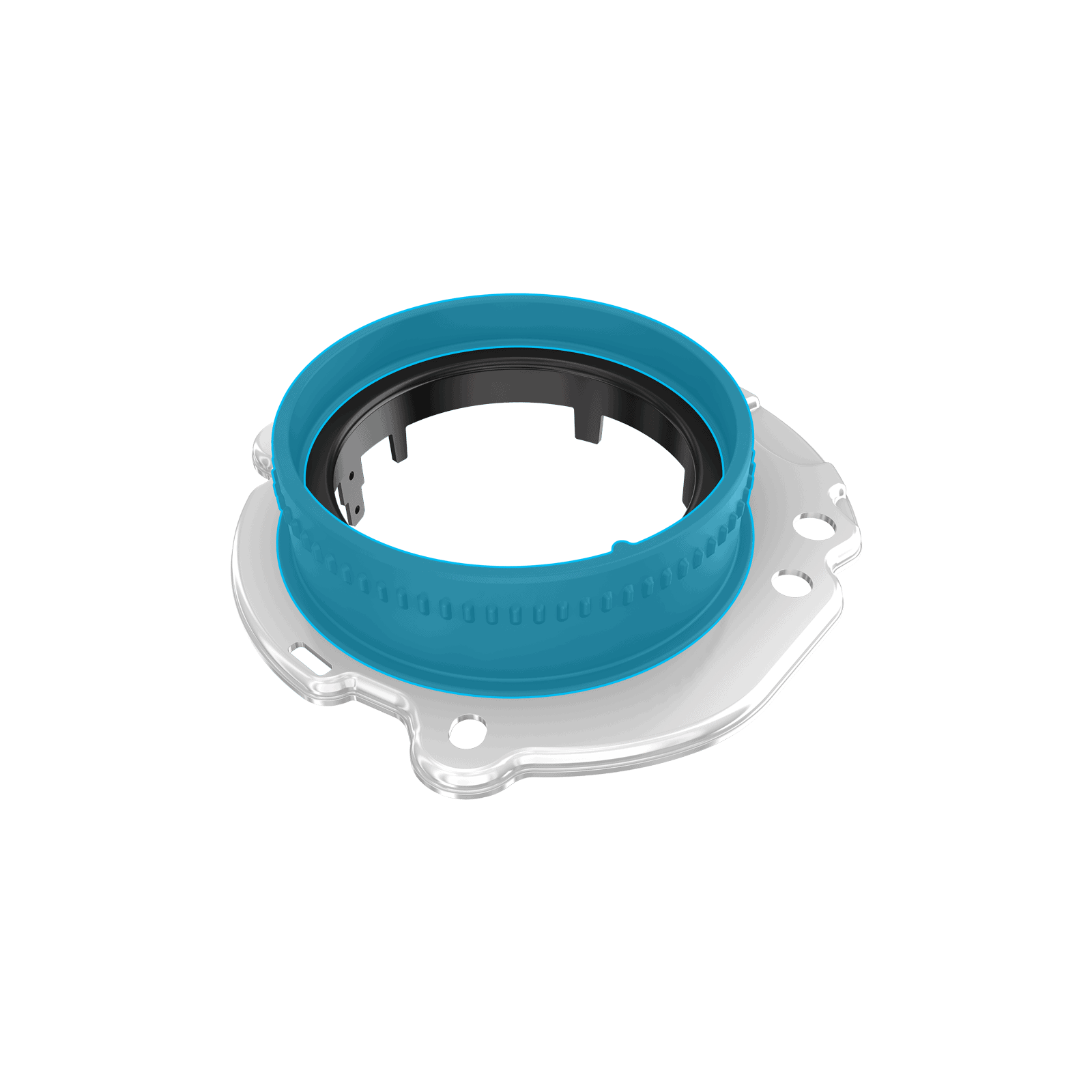

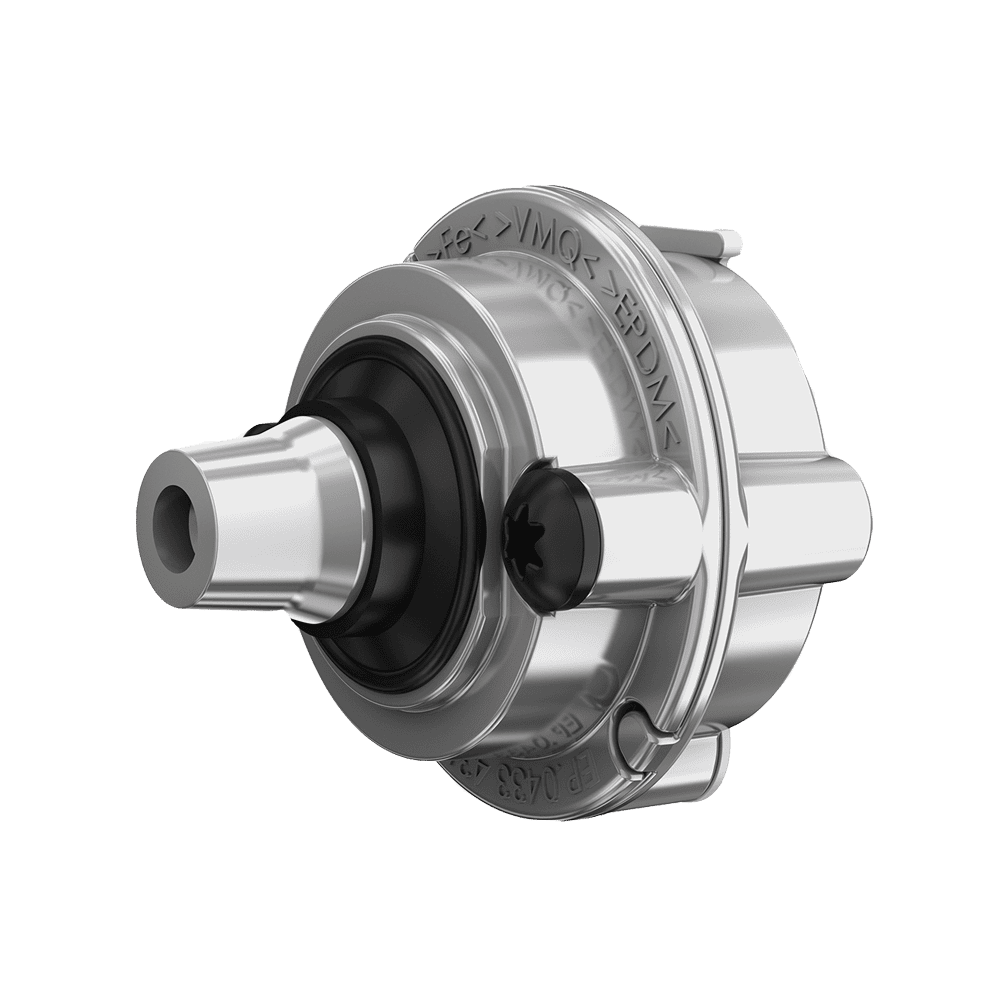

Steering Wheel Inflator Damper

Vibracoustic’s steering wheel inflator dampers are compact and minimize additional mass by utilizing the airbag inflator as part of the damping system. Vibracoustic has solutions for inflators both with and without flange. Both these solutions have no impact on the safe function and deployment of the airbag.

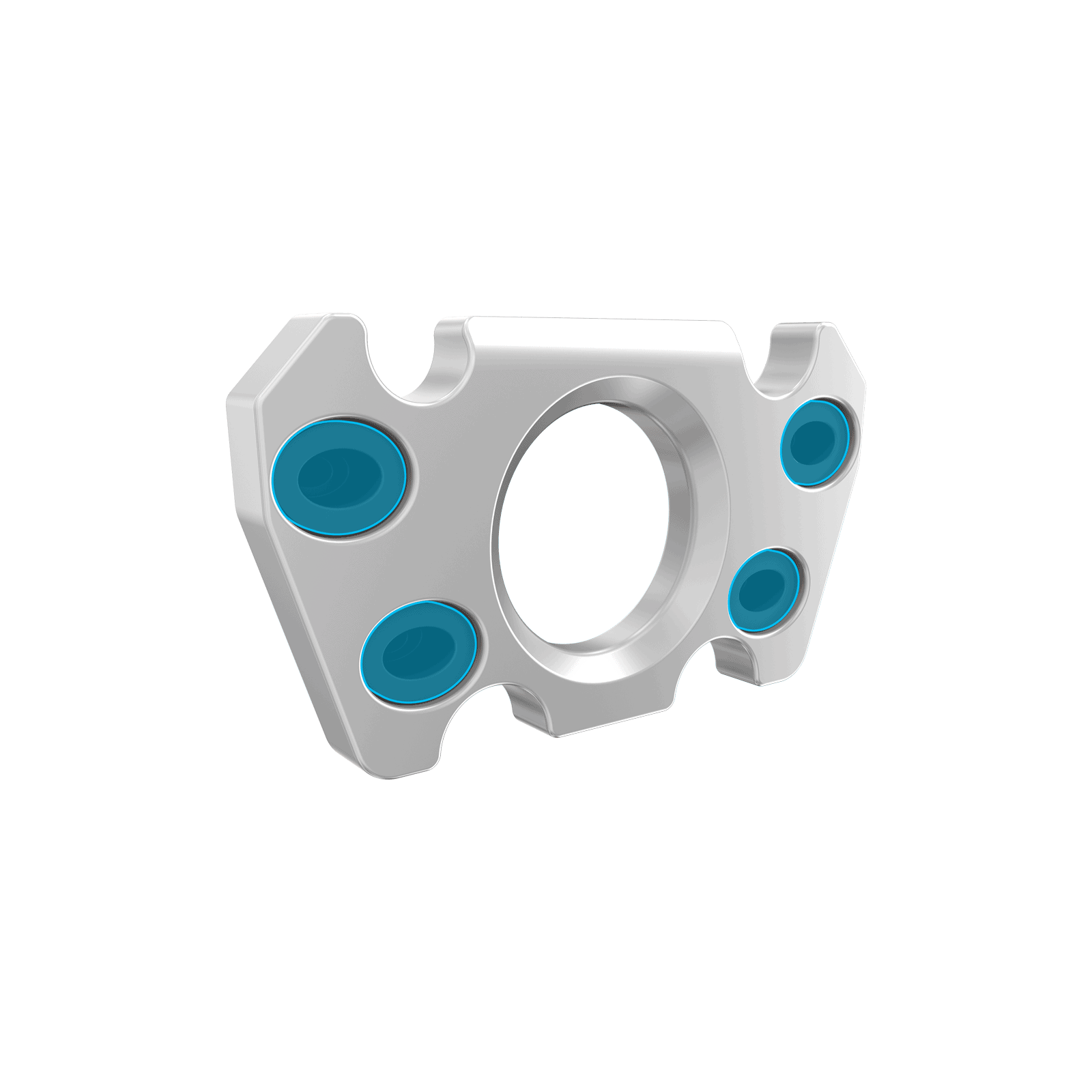

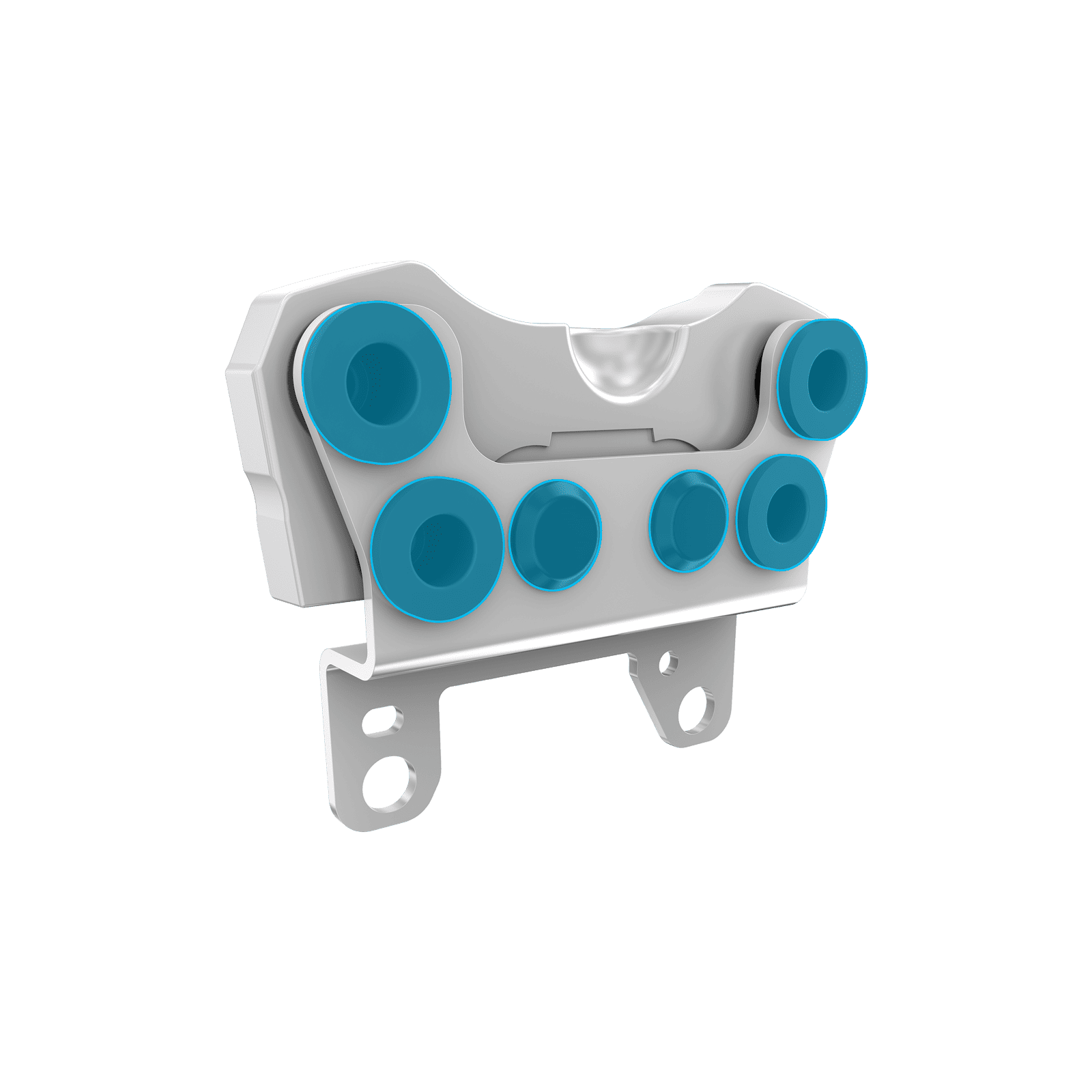

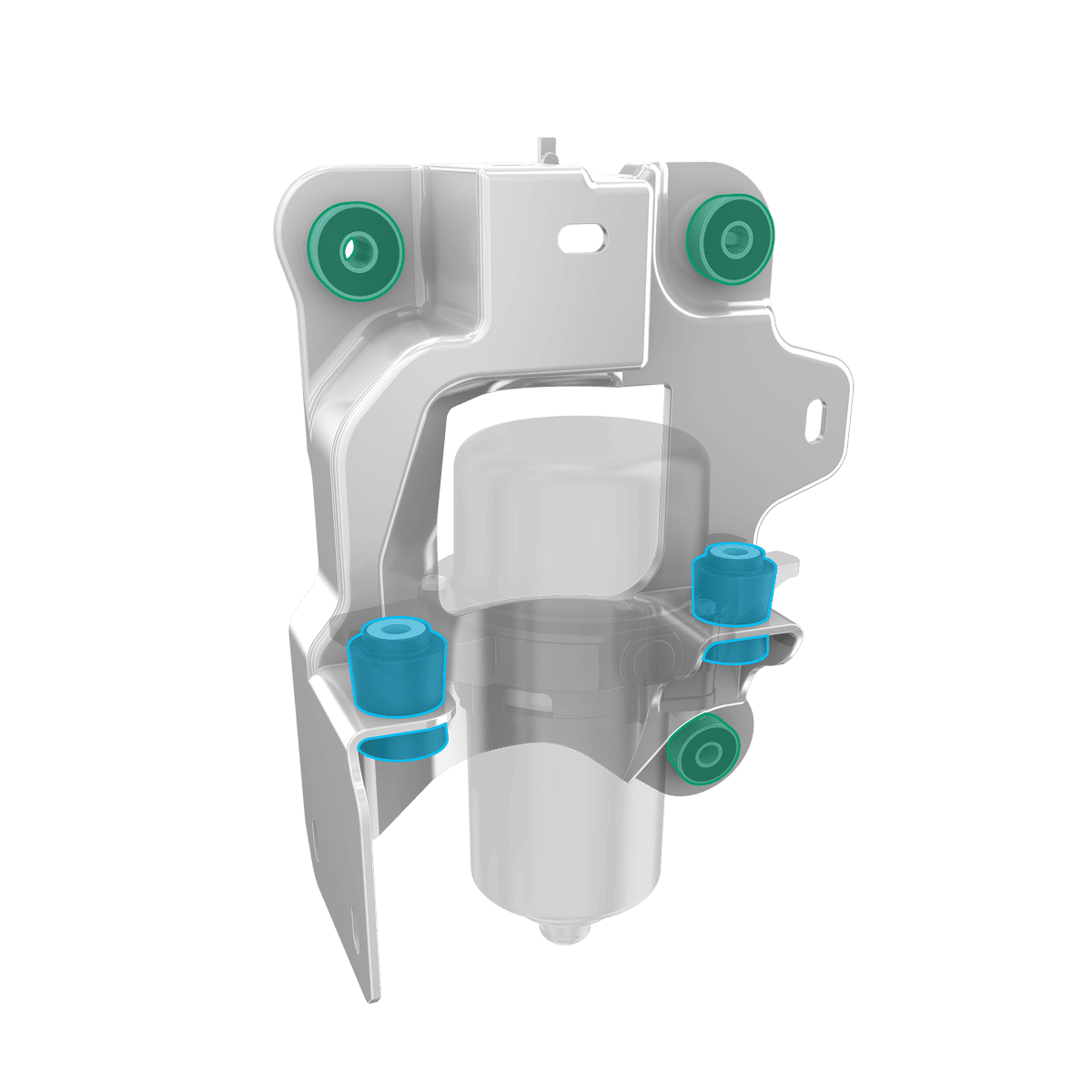

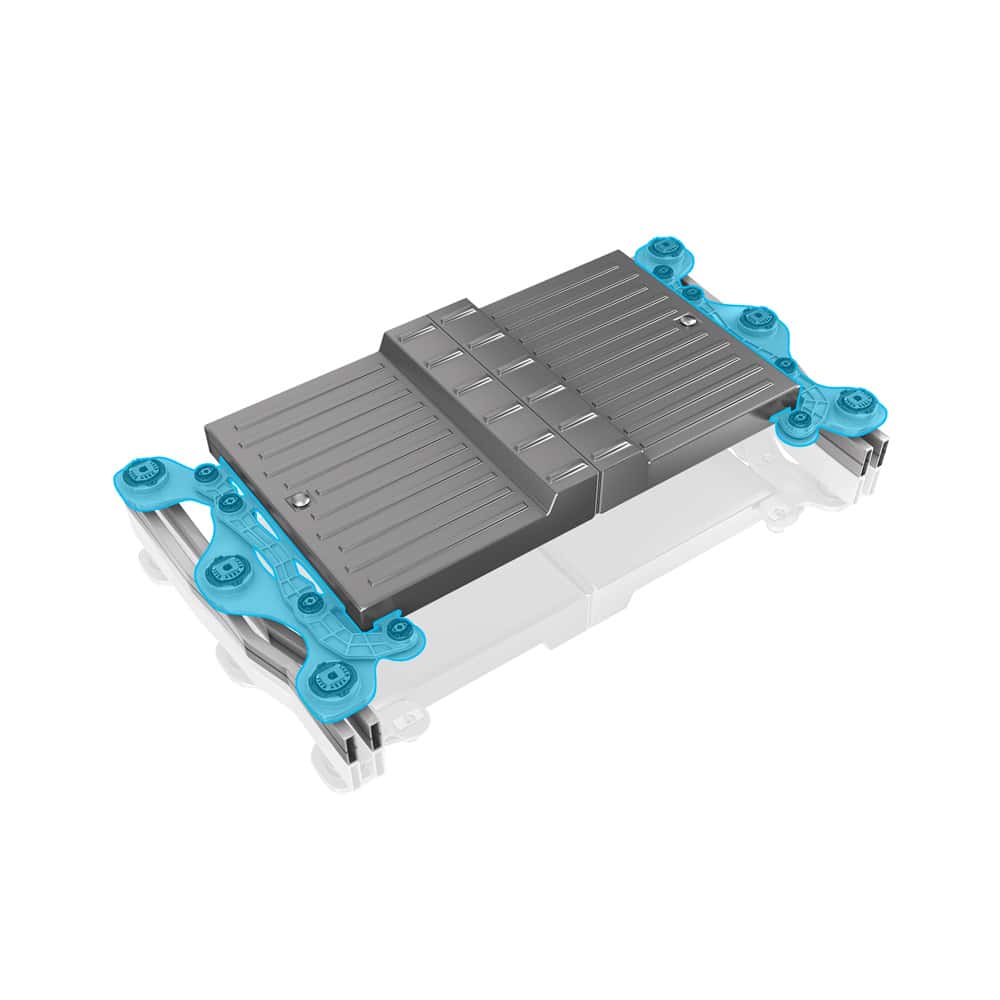

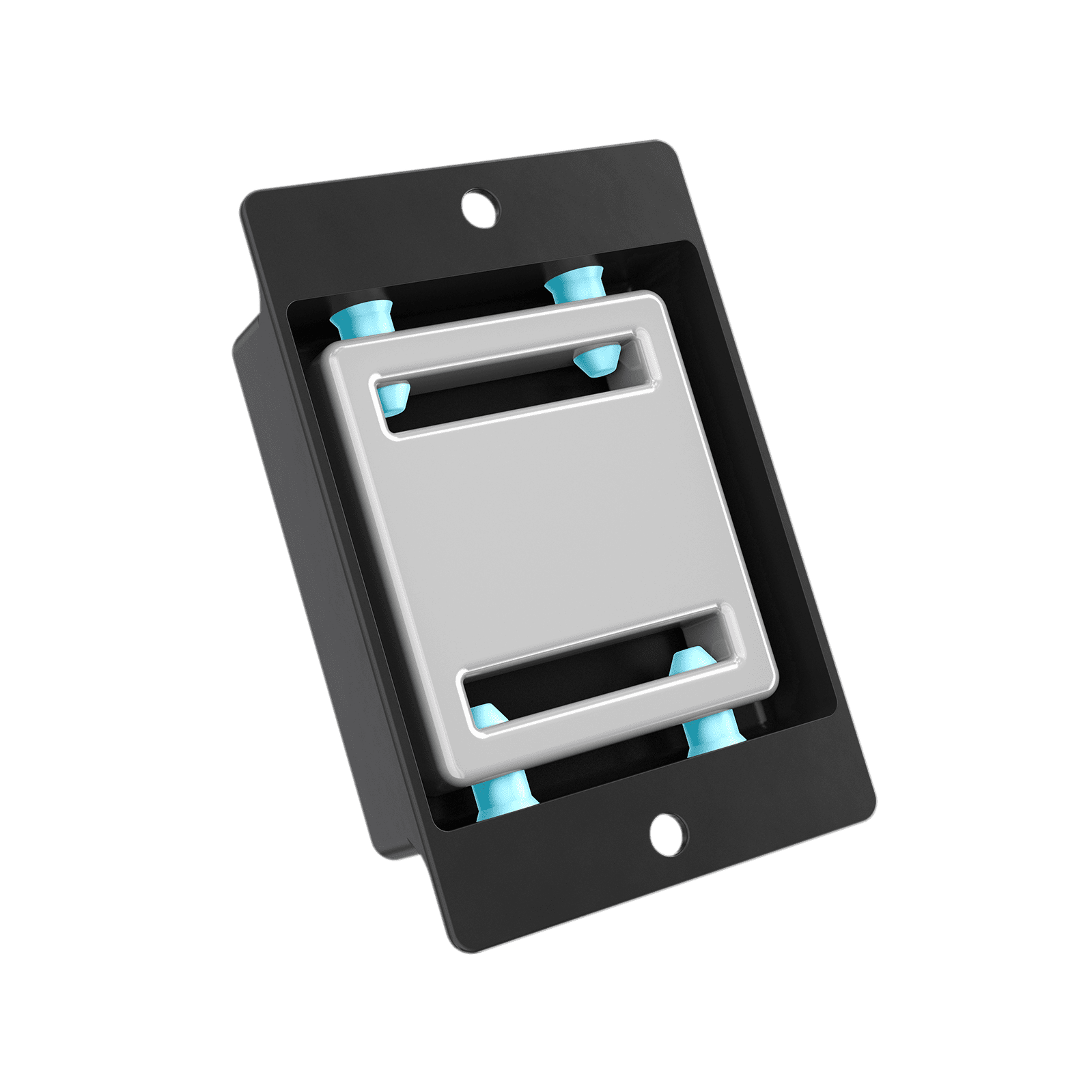

Steering Wheel Module Dampers

An innovative and cost-effective solution to managing steering wheel NVH challenges, the module dampers utilize the steering wheel’s DAB-module (Driver Air Bag-module) as the moving mass. They attach to the steering wheel frame and are the smallest available steering damper solution, allowing for greater DAB-module design freedom. The module dampers are made from liquid silicone rubber with a plastic internal structure. They are easy to assemble, with a simple snap-fit and screw, while also offering broad performance for very little additional weight and material. To further simplify the assembly process for the customers, a full assembly including plastic overmolding of the horn plate can also be supplied. This solution has no impact on the safe function and deployment of the airbag.