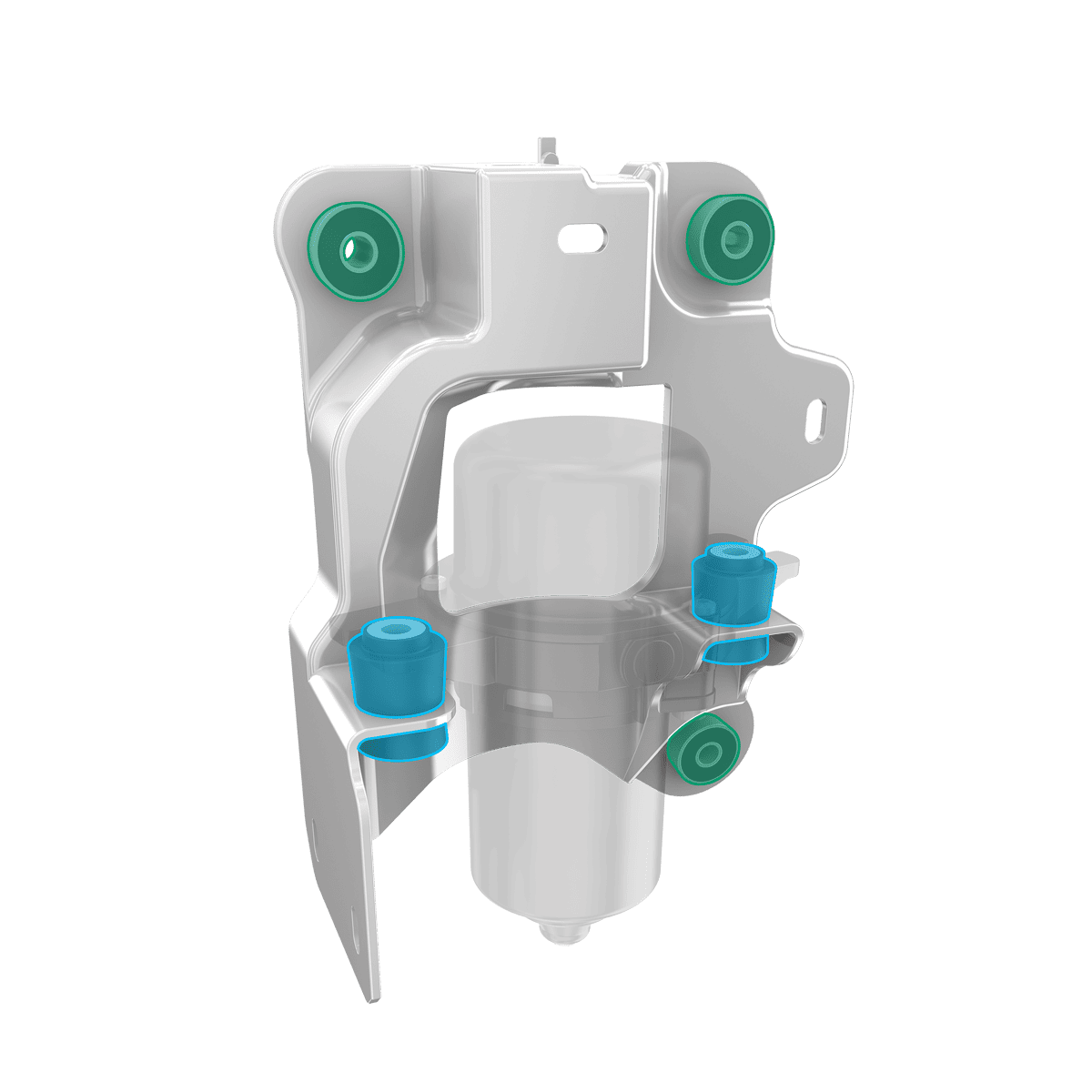

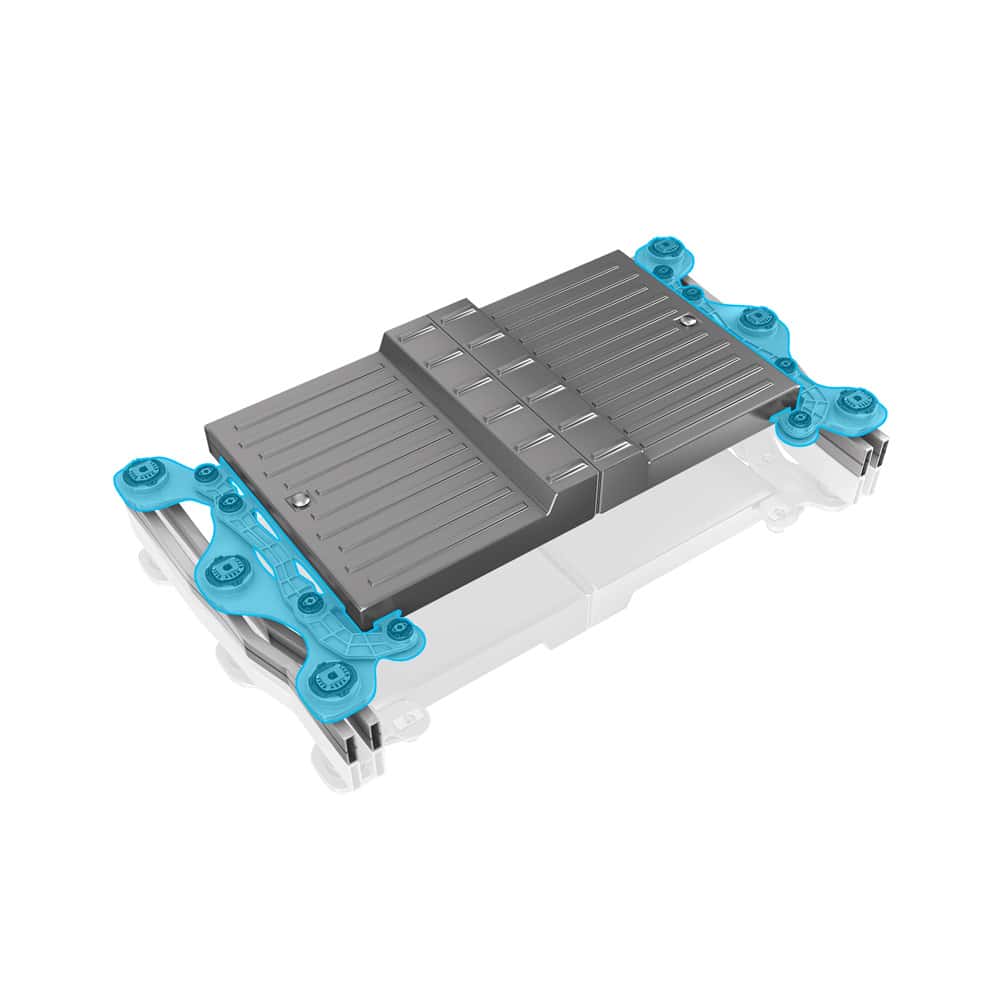

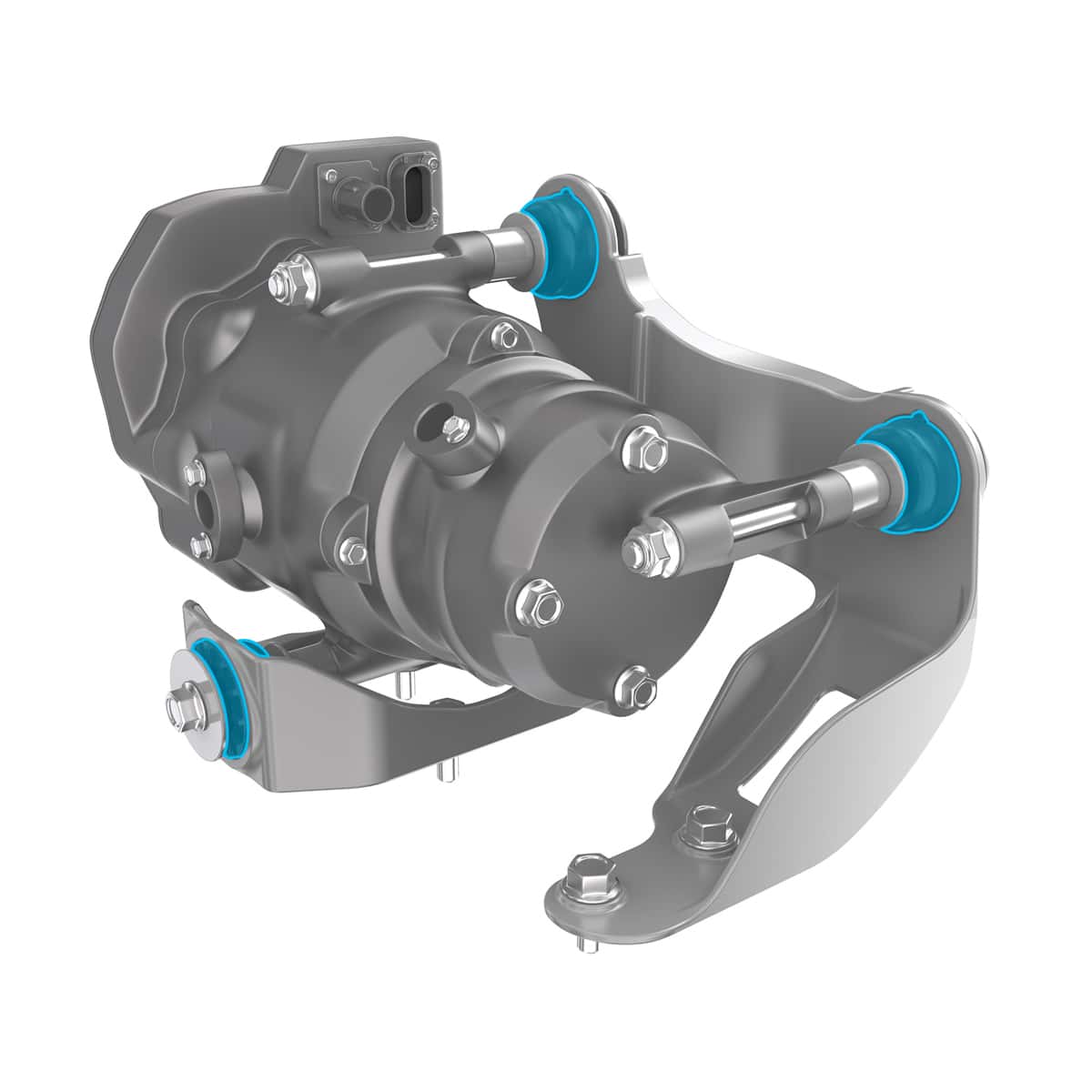

Seat Dampers

Reduce seat vibrations with opposing inertial forces

Lightweight glass fiber housing possible

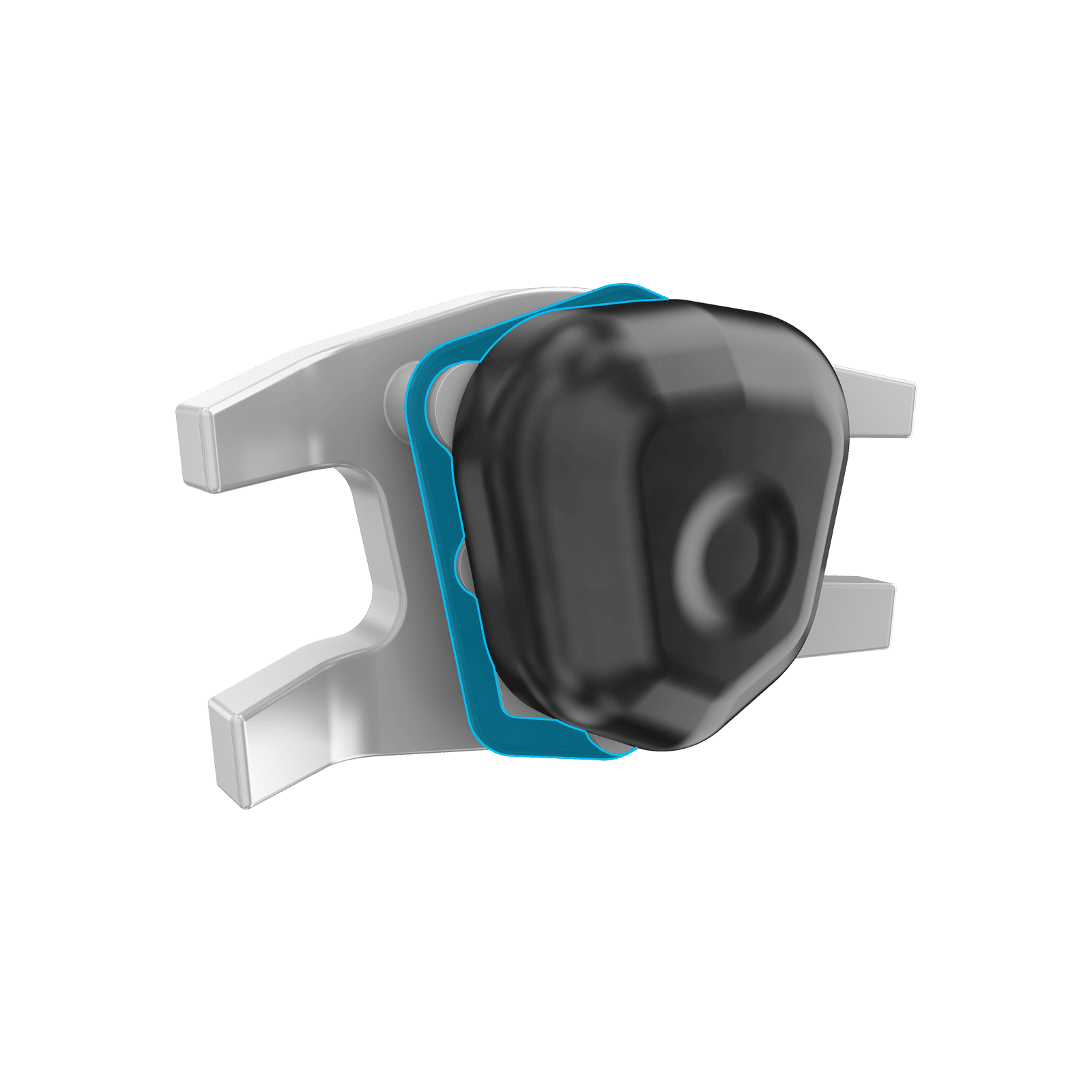

Reqill liquid silicone rubber with very good temperature characteristics

Color coding possible for identification

Die-casted zinc providing moving mass for damper

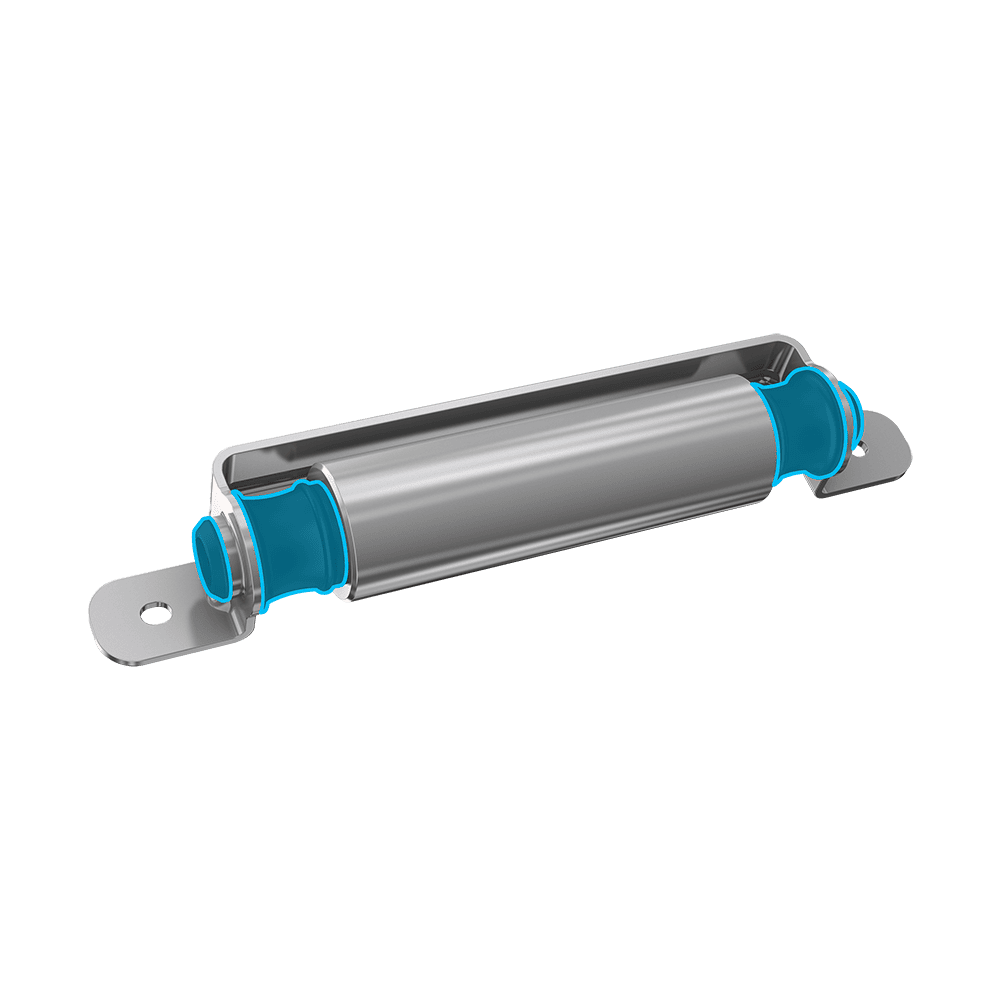

Tuned mass dampers are ideal for applications where vibrations transmitted from the road surface into the chassis need to be balanced with opposing inertial forces. One application area is reducing seat vibrations. Unresolved, these can lead to quality complaints from customers prevented from enjoying rear-seat entertainment systems.

Rear-seat entertainment systems are becoming increasingly popular, not just in premium sedans, but also in family vehicles. To get the fullest enjoyment from movies or games, the vibration behavior of the front seats, where the screens are mounted, needs to be improved.

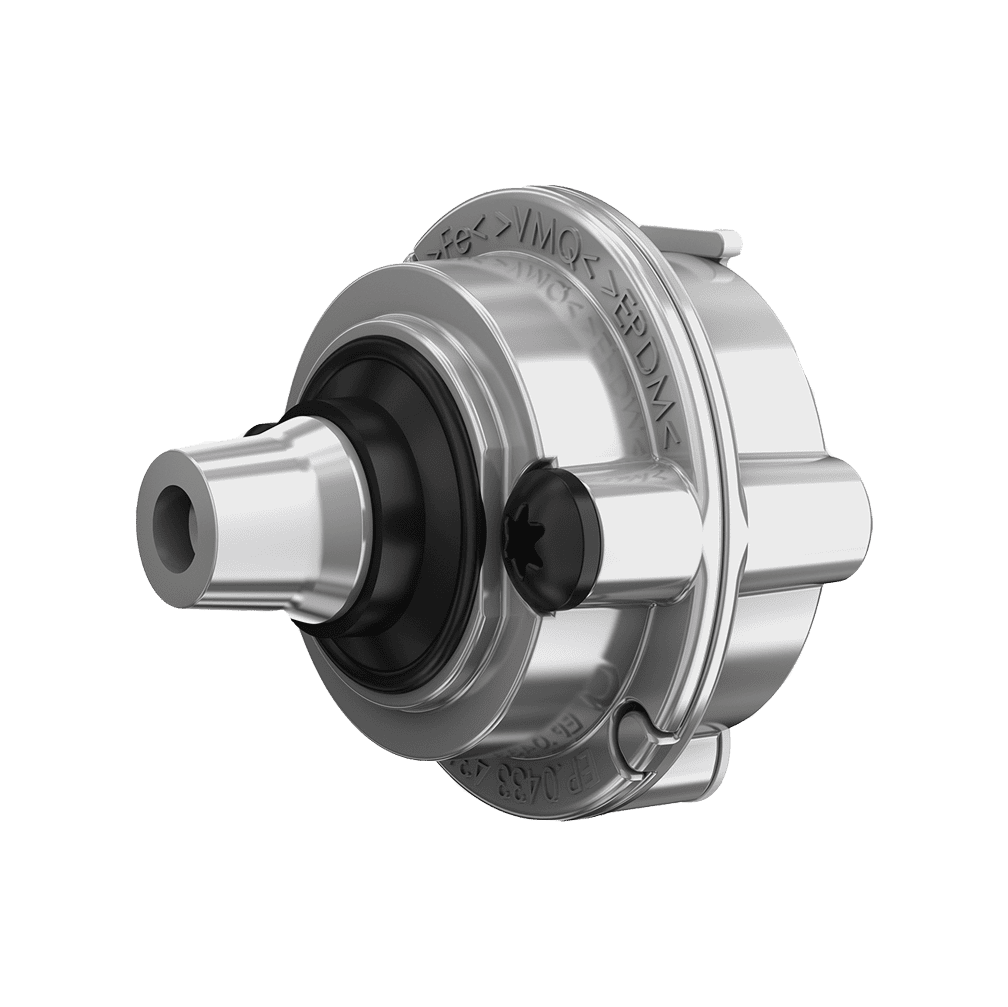

The often-visible vibrations of an unoccupied seat can lead to quality complaints from customers. To address customers’ specific frequency needs, die-cast materials like zinc can provide the moving mass for the damper, while lightweight glass fiber re-inforced plastic housings can reduce the weight. Silicone rubber is used to mount the moving mass into the housing and provides the damping characteristics. It has very good temperature characteristics and can also be color coded for better identification during assembly.