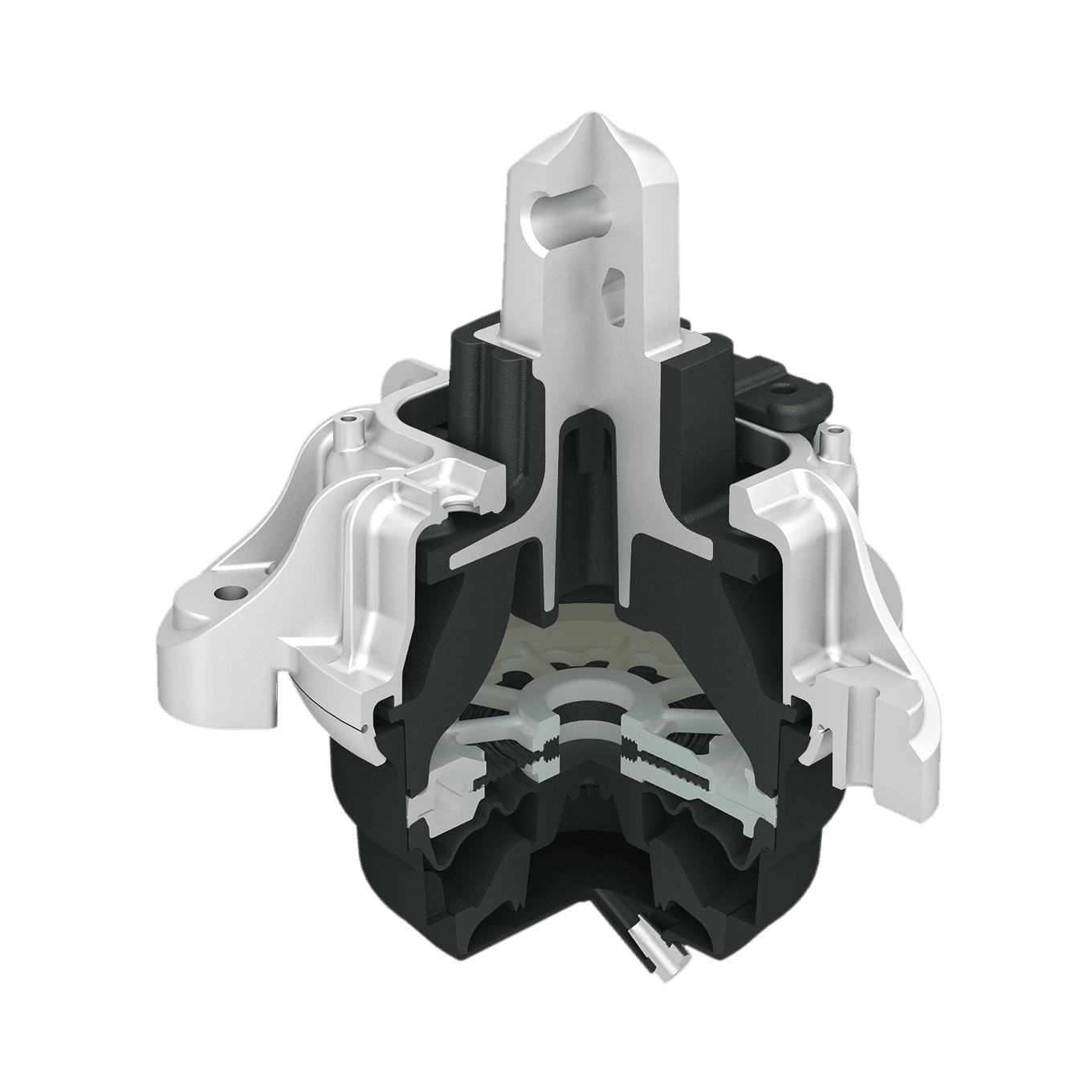

Modular Motor Mount Bracket with TPE Bushing

Lightweight solution with thermoplastic elastomer (TPE) bushing and integrated damper mass – offers double isolation and improved efficiency.

Modular

Double isolation

Lightweight

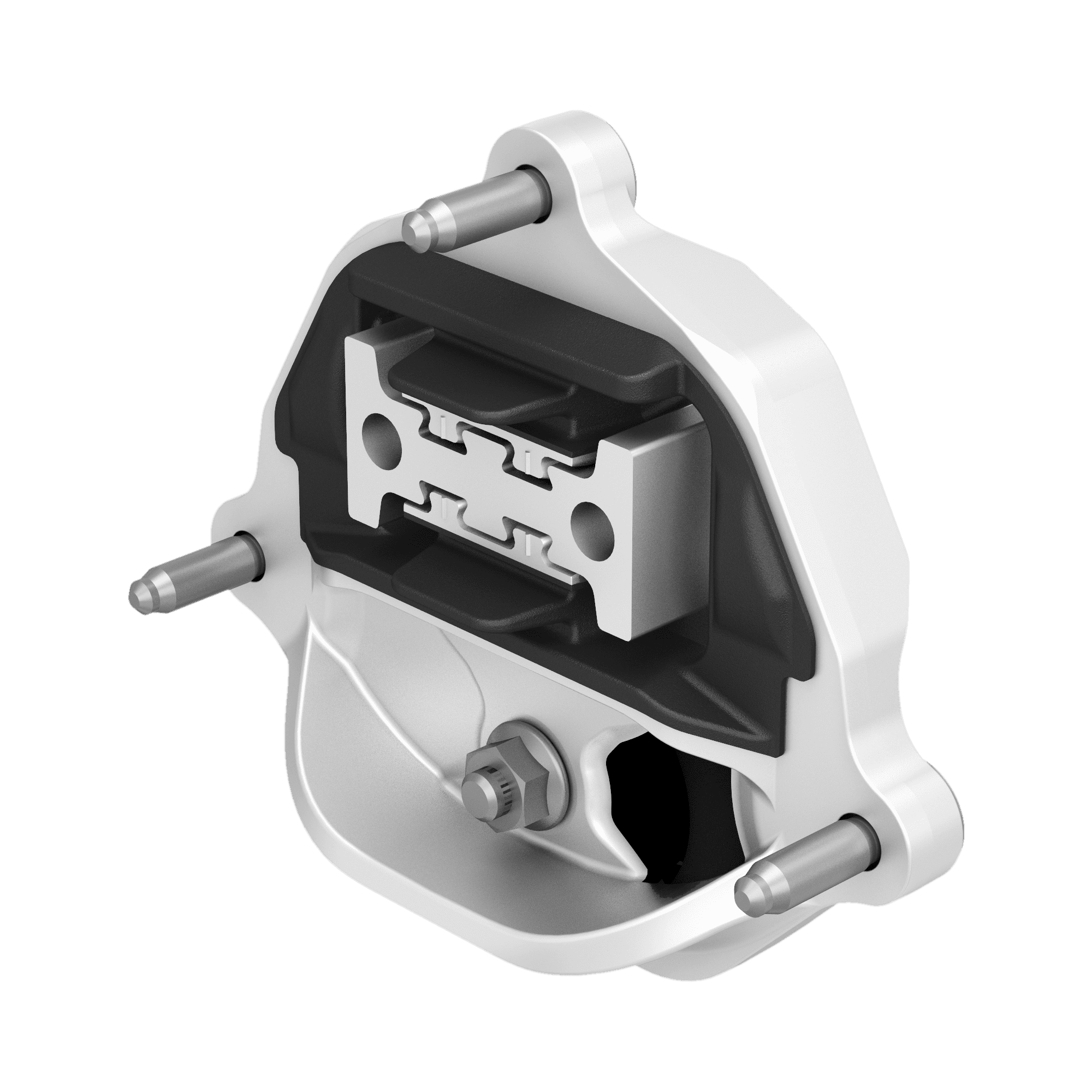

The compact polymer beam structure and the integrated thermoplastic elastomer bushings allow full integration, weight reduction and simplified assembly. The modular mounting solution is available with different levels of integration – raging from bushing to more complex beam structures which can be finetuned to specific stiffnesses and isolation requirements. The modular motor mount bracket and a highly-integrated beam mounting structure was specifically developed for BEVs to meet the requirements for EDU mounting.

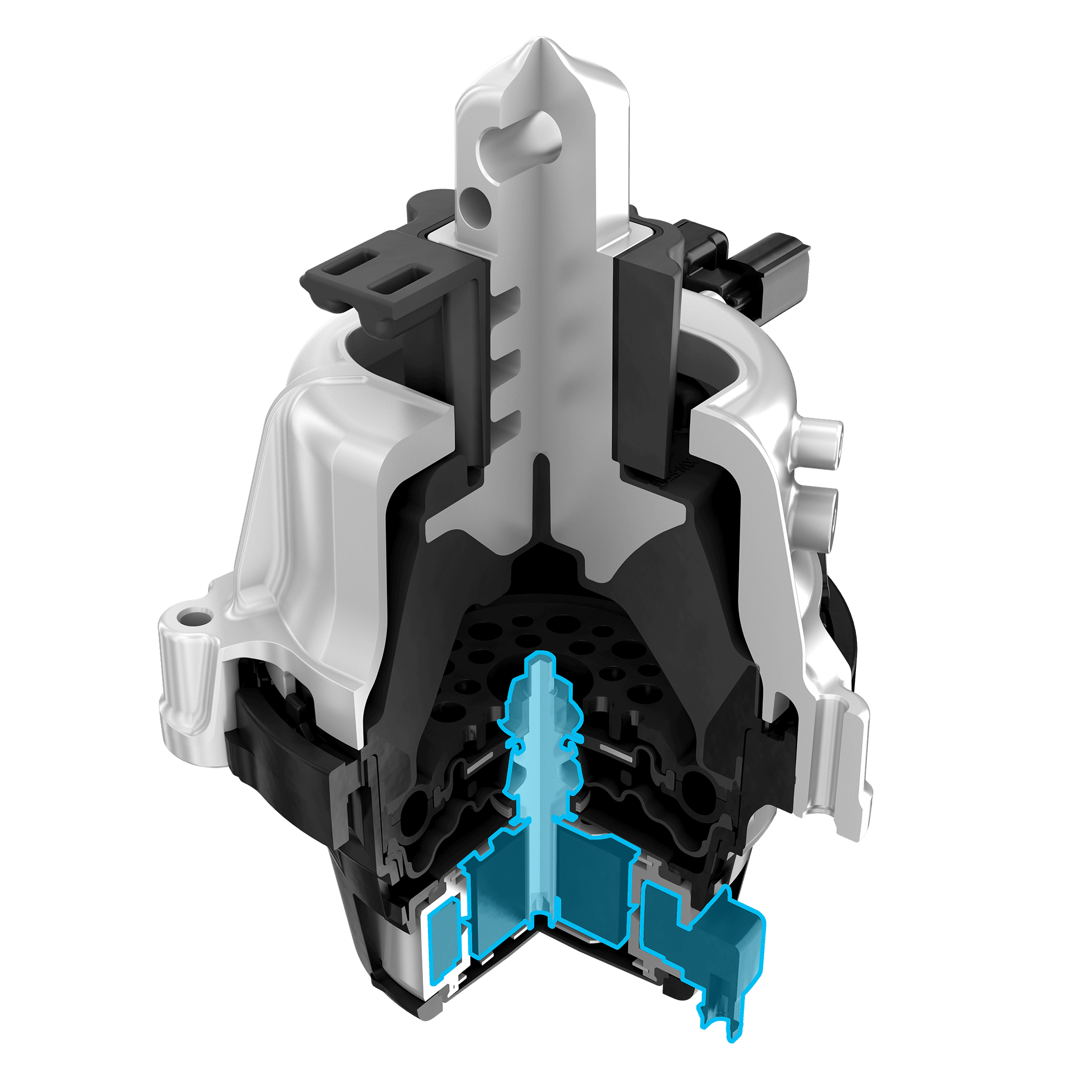

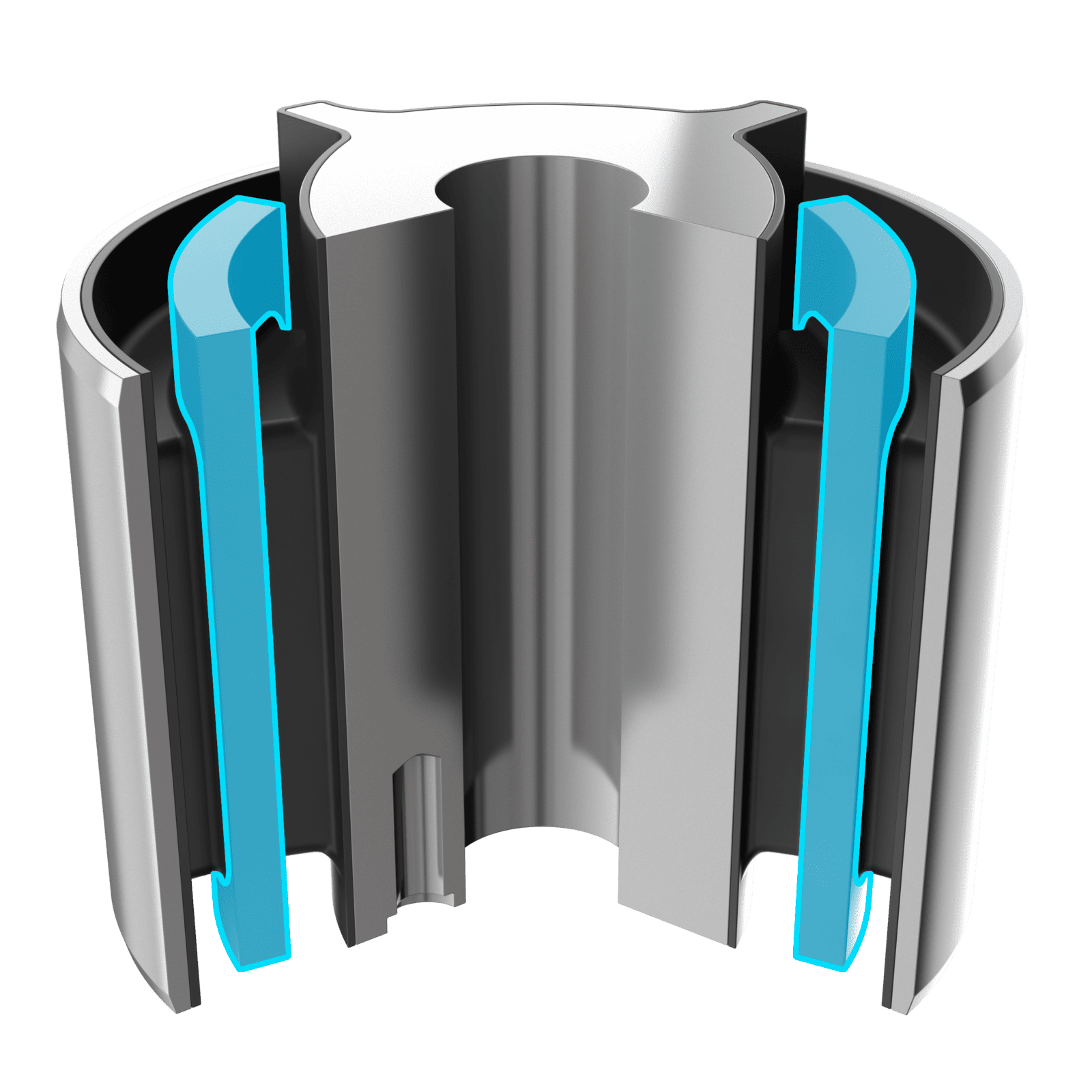

TPE Bushing

The thermoplastic elastomer (TPE) bushing provides double isolation for improved efficiency, with the entire part acting as a damper. This mount offers cost savings through dual injection production technique and can be tailored to the desired stiffness by simply changing the geometry. The use of TPE in NVH applications is an innovative alternative to natural rubber.

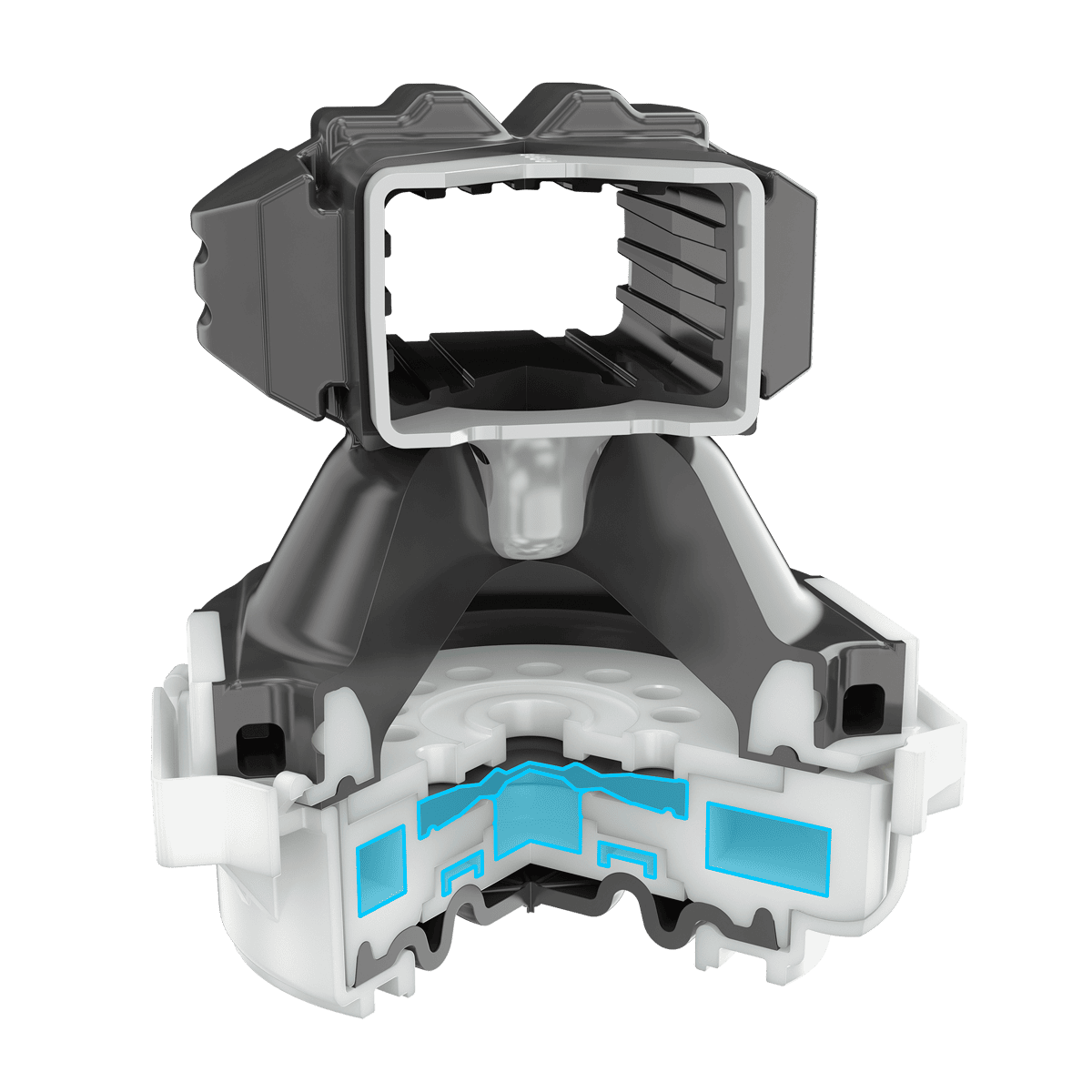

Compact beam structure with integrated bushings

Our patented lightweight, compact composite or polymer ‘beam’ structure combines the same TPE bushings and double isolation technology while further optimizing NVH management. It provides significant weight savings of up to 25%, is smaller than comparable alternatives and simple to assemble which leads to reduced cost. Additionally, its plastic-based construction offers better isolation of higher frequencies, like those associated with EDU operation, when compared to a steel or aluminum solution. Our engineering team also integrated a damper mass into the beam’s construction which further optimizes NVH performance without compromising packaging.