Gearbox Mounts

Eliminate gearbox whine, generate weight and cost savings, and improve durability

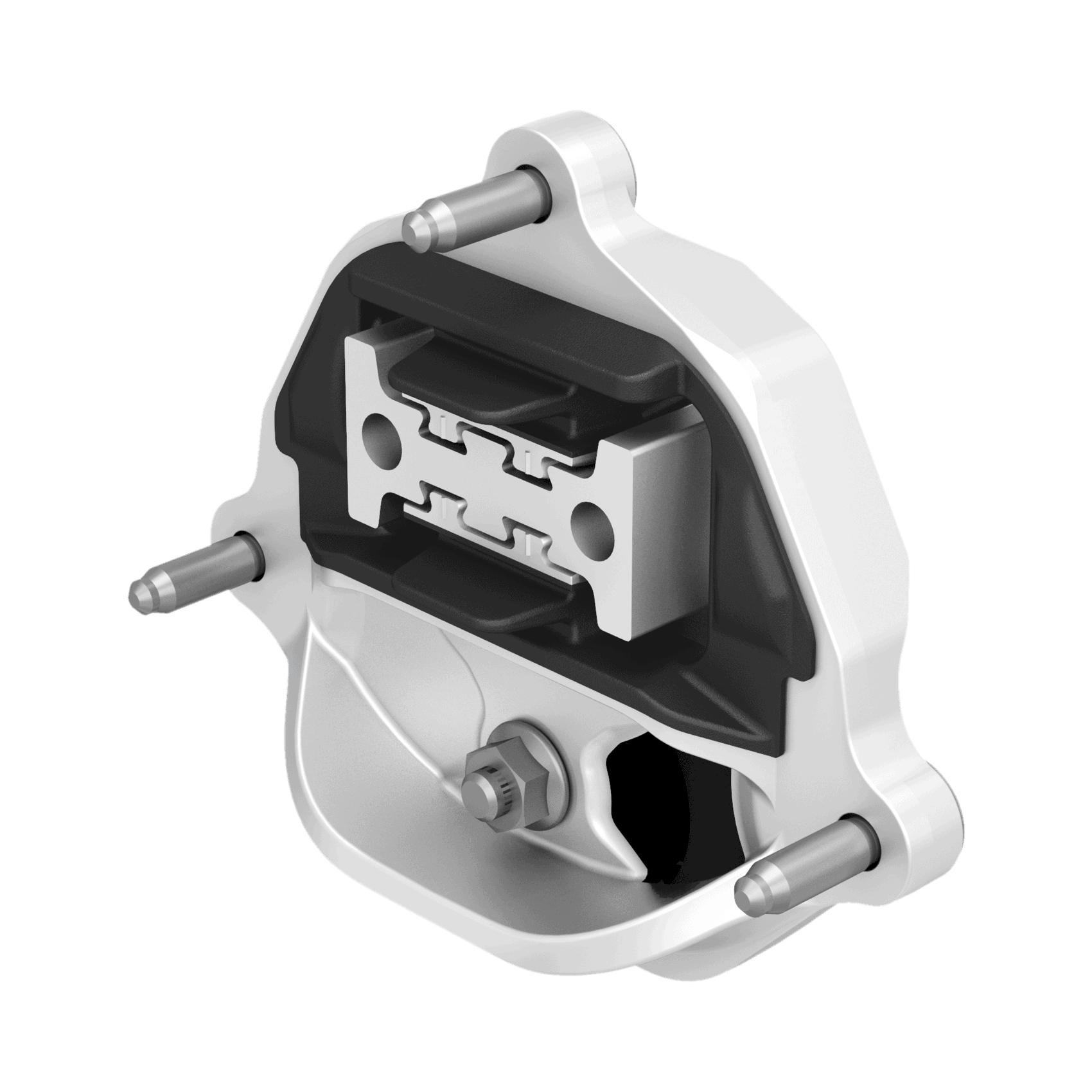

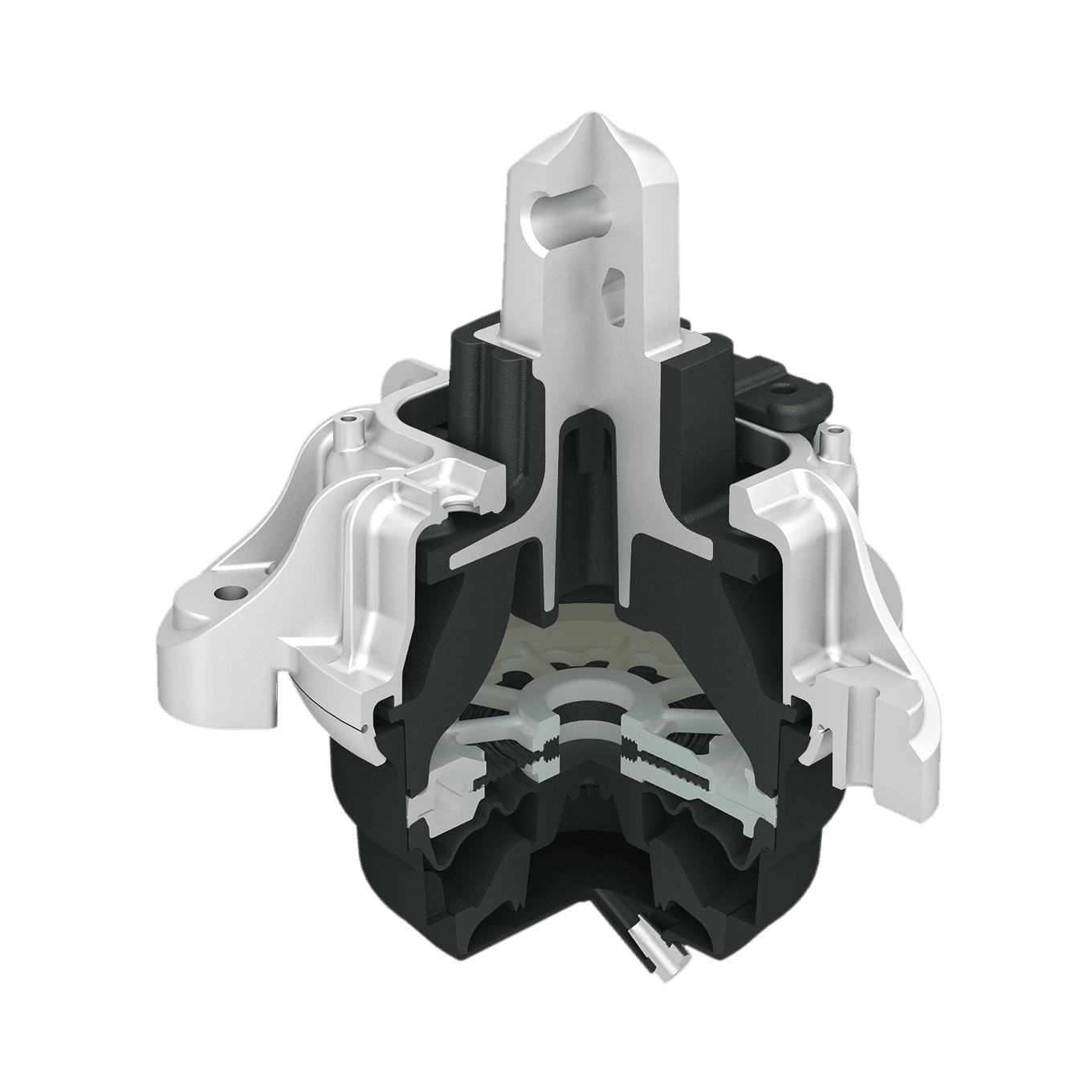

Lightweight aluminum housing and compact design for tight packaging space

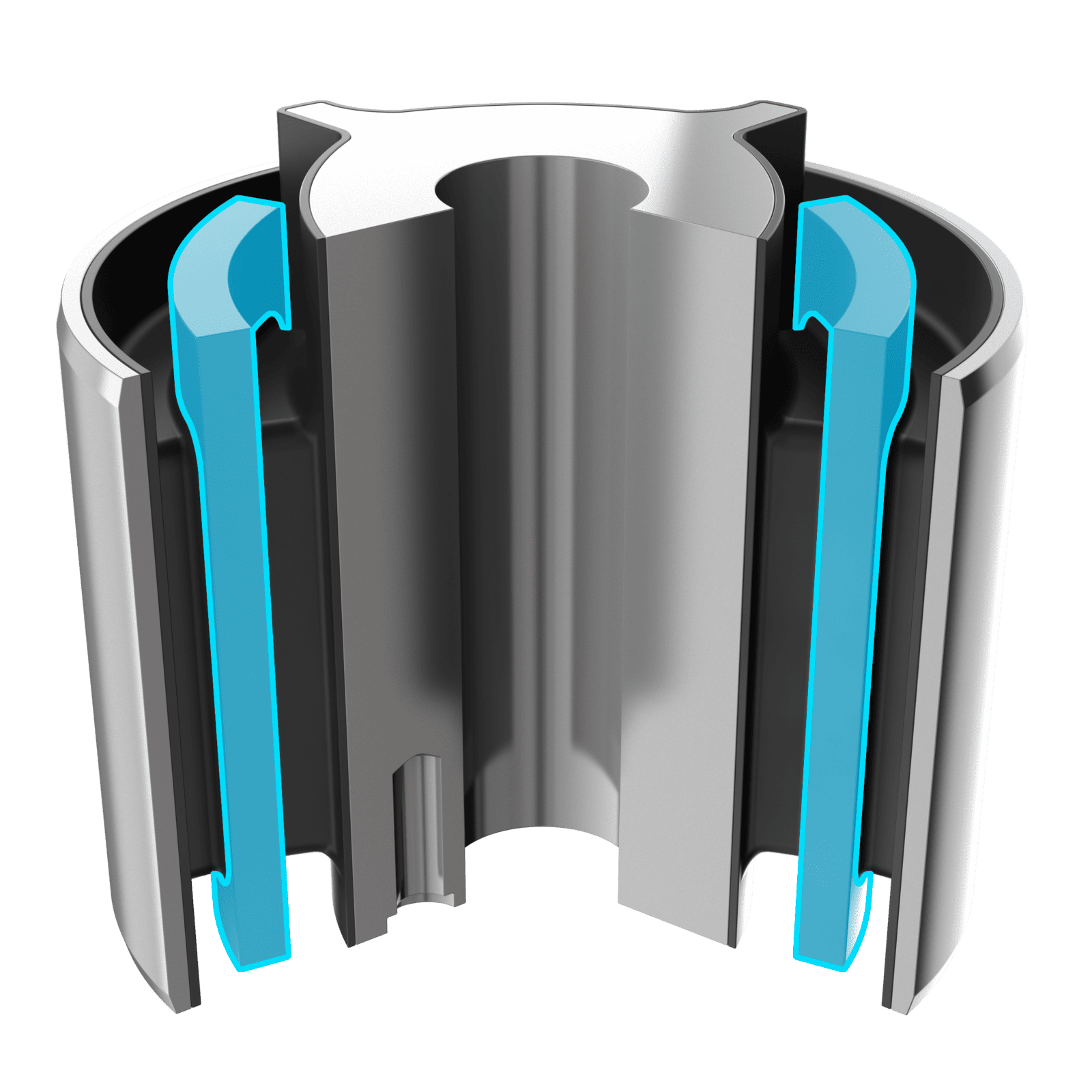

Rubber flaps act as cost-efficient tunable mass absorbers

Especially suitable for gearbox and electro motor mounts

Better high frequency isolation and improved vehicle interior noise

New manual – and especially automatic – transmission designs with more gears are increasingly common in order to maximize fuel economy without impacting power output. Gearbox mounts address the Noise, Vibration and Harshness issues deriving from these new transmission designs. This gearbox mounting solution eliminates gearbox whine, generates weight and cost savings, and improves system durability.

Having more gears means that gears are running with little or no load for longer periods of time, creating a high frequency whining noise that is more audible.

Traditional solutions focus on mass damper technology, where the gearbox is mounted on conventional rubber mounts and a large mass damper is added to counter the high-frequency vibration.

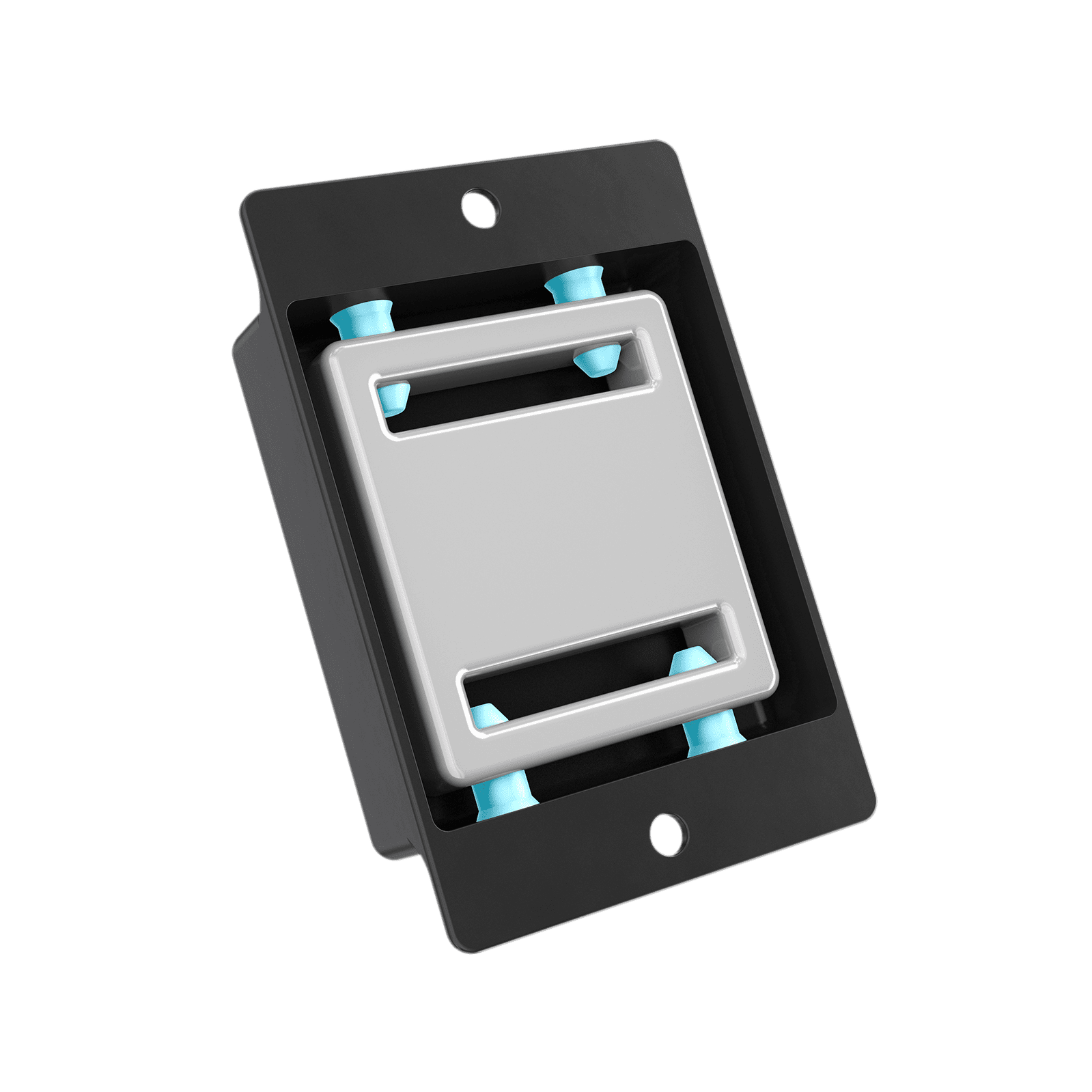

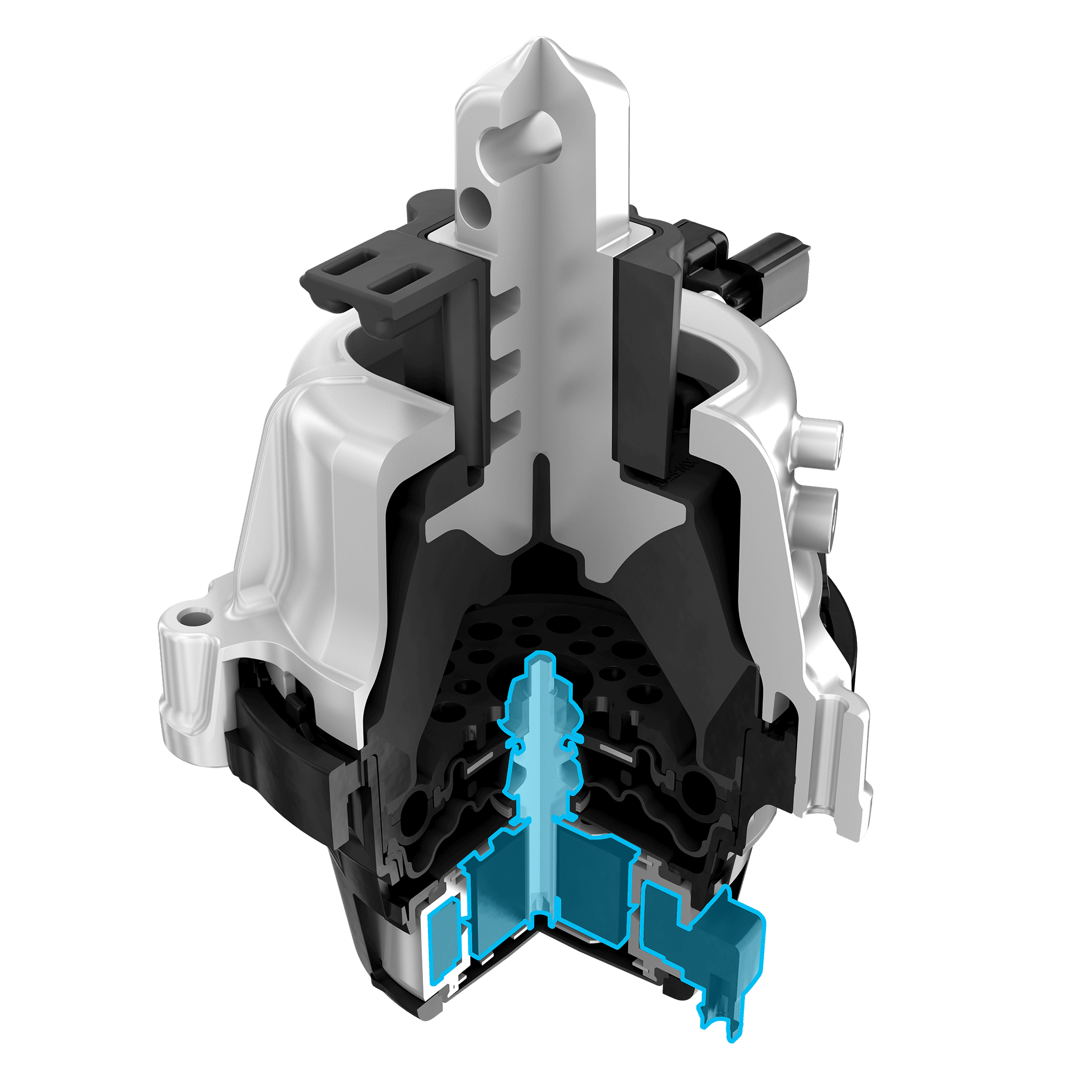

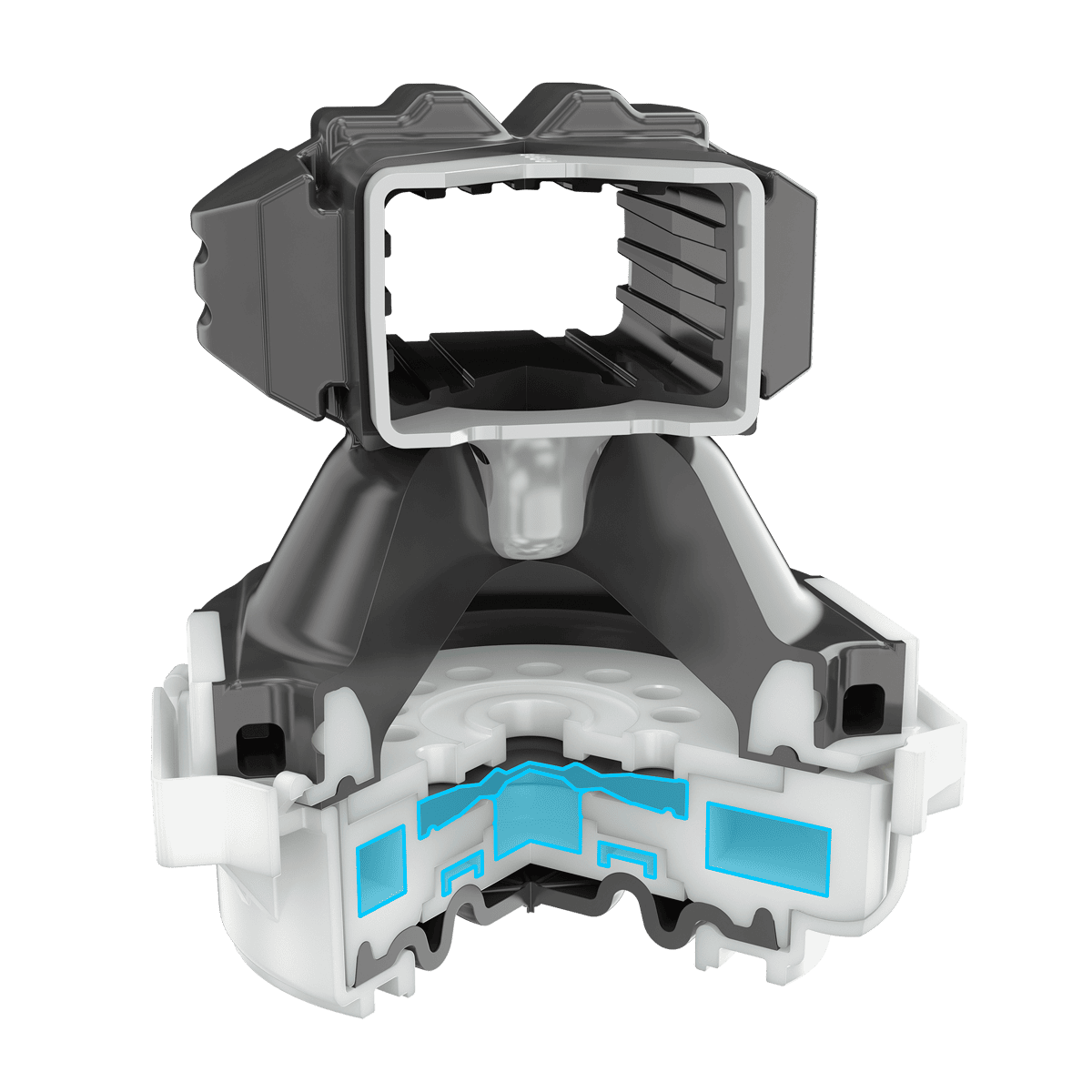

To avoid additional mass, rubber flaps on both main springs act as cost-efficient tunable mass absorbers. A modular design uses an inserted core to achieve efficient variable precompression of the rubber spring. This results in better high-frequency isolation, leading to improved vehicle interior noise and significant weight and cost savings. A lightweight aluminum housing and a compact design enable strict packaging demands to be met.

Furthermore, the mount can be easily tuned to address specific frequencies, making it suitable for multiple applications. The essential feature of the product are the rubber flaps on both sides of the main spring. Using advanced design tools, the thickness and height of these flaps can be tuned to target multiple frequencies, resulting in better high frequency isolation and improved vehicle interior noise.

As high-frequency isolation is a requirement for electric motors, these mount features are also suitable for electric motor mounting solutions.