eCompressor Decoupling

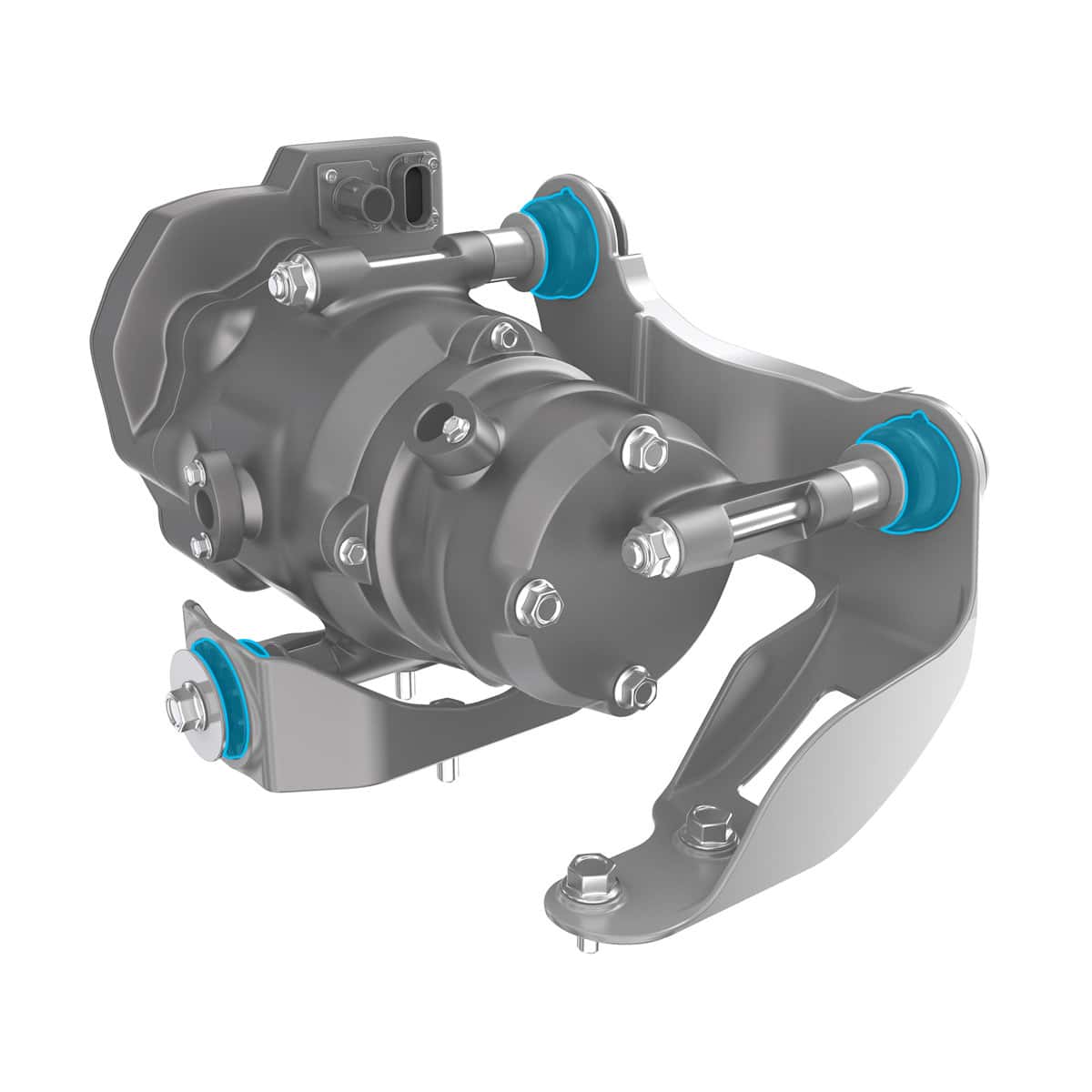

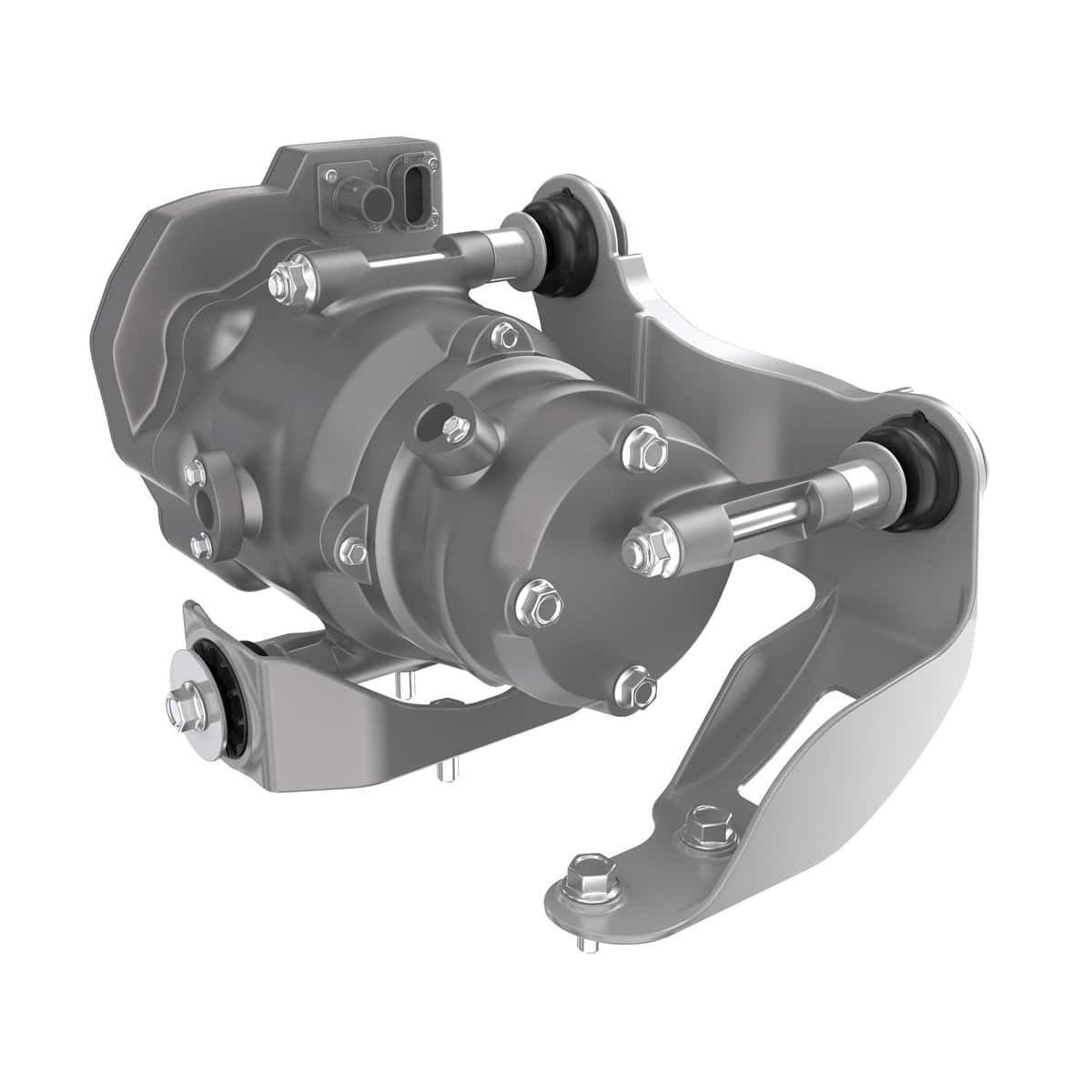

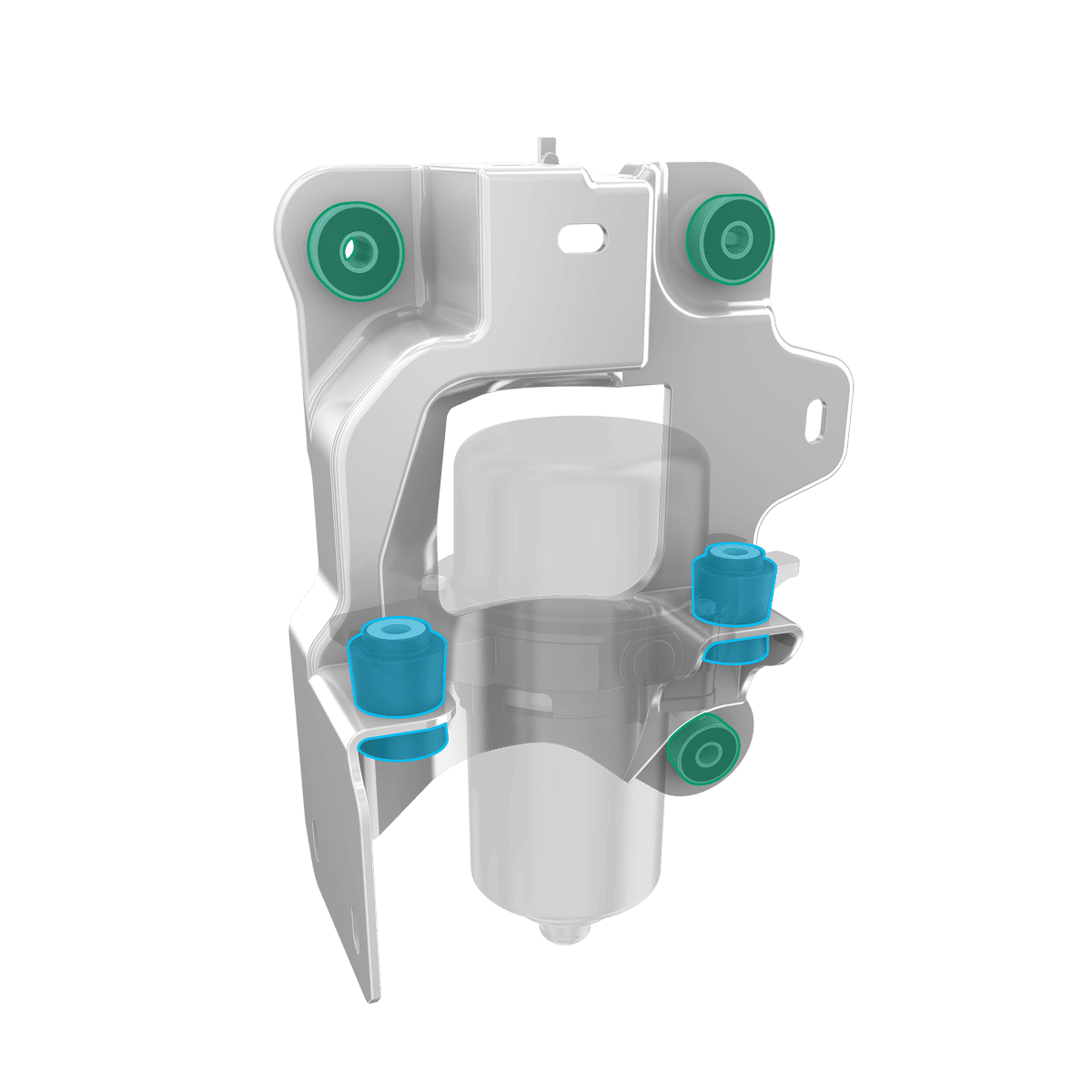

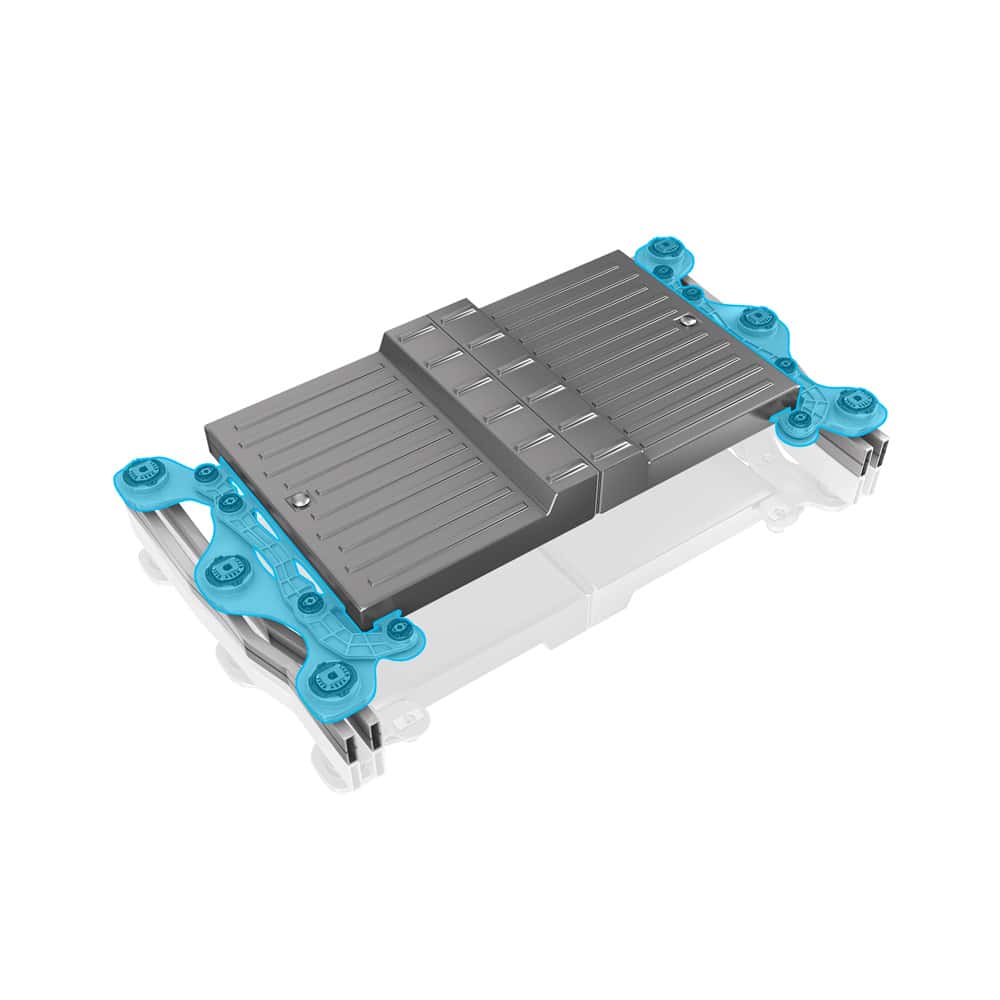

The decoupling system for eCompressors solves many of the NVH challenges in balancing thermal management with excessive noise and vibration from highly loaded eCompressors.

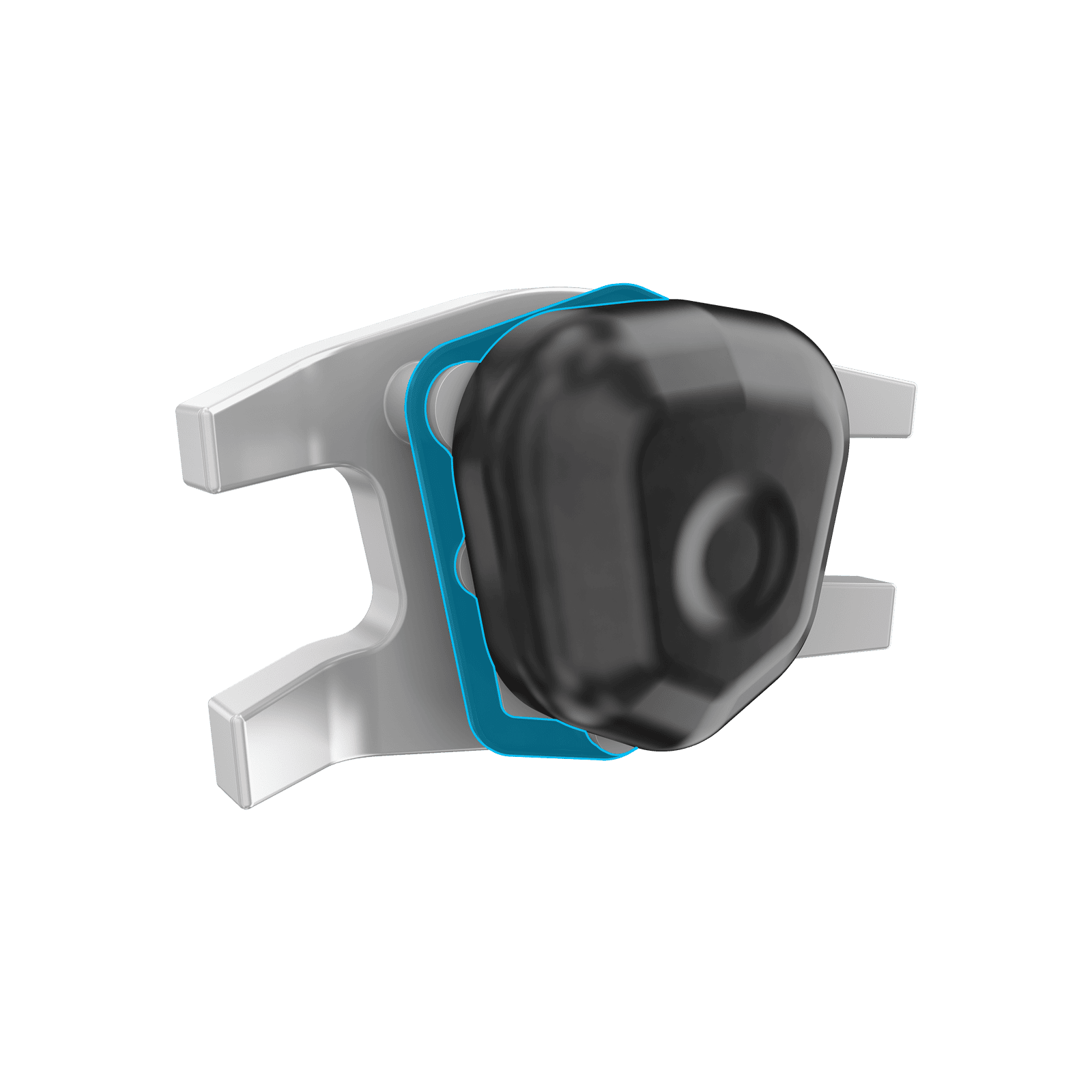

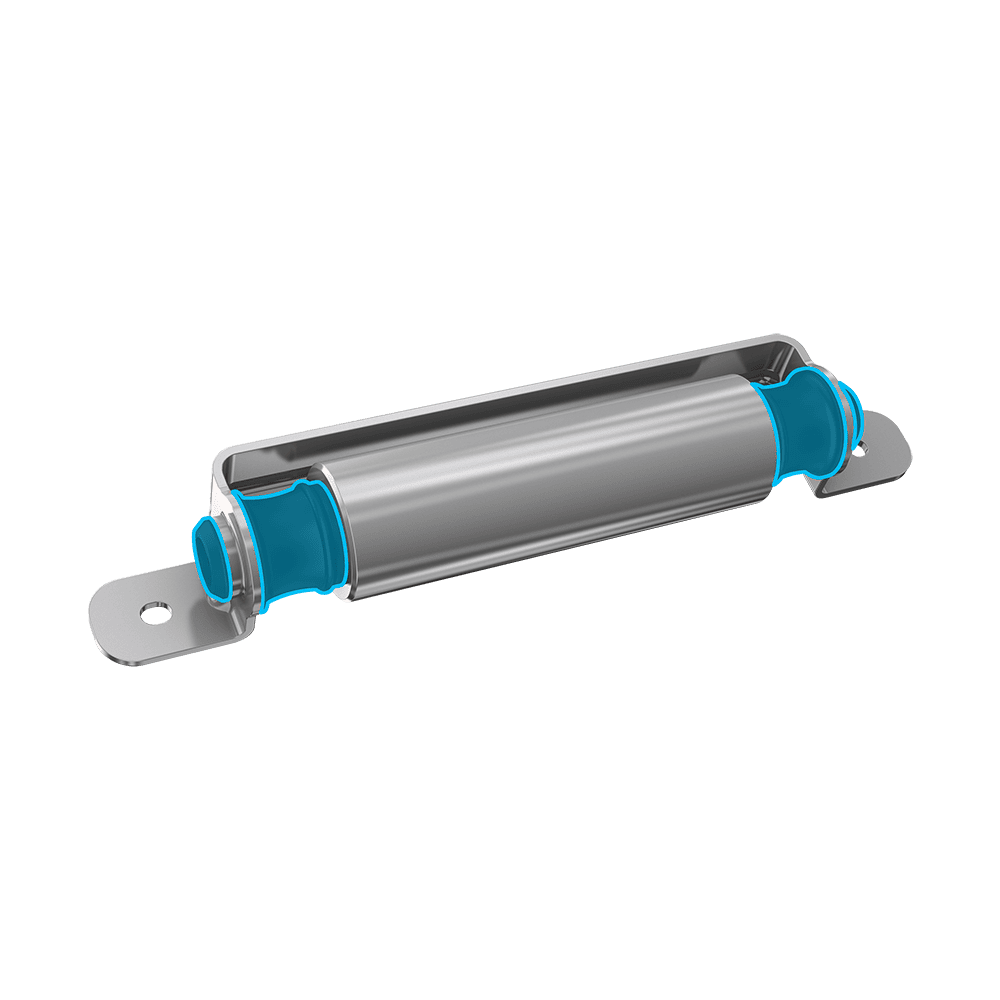

Low stiffness with special rubber shapes with integrated travel-limiters possible

Durability prediction and topology-optimization for best cost and design

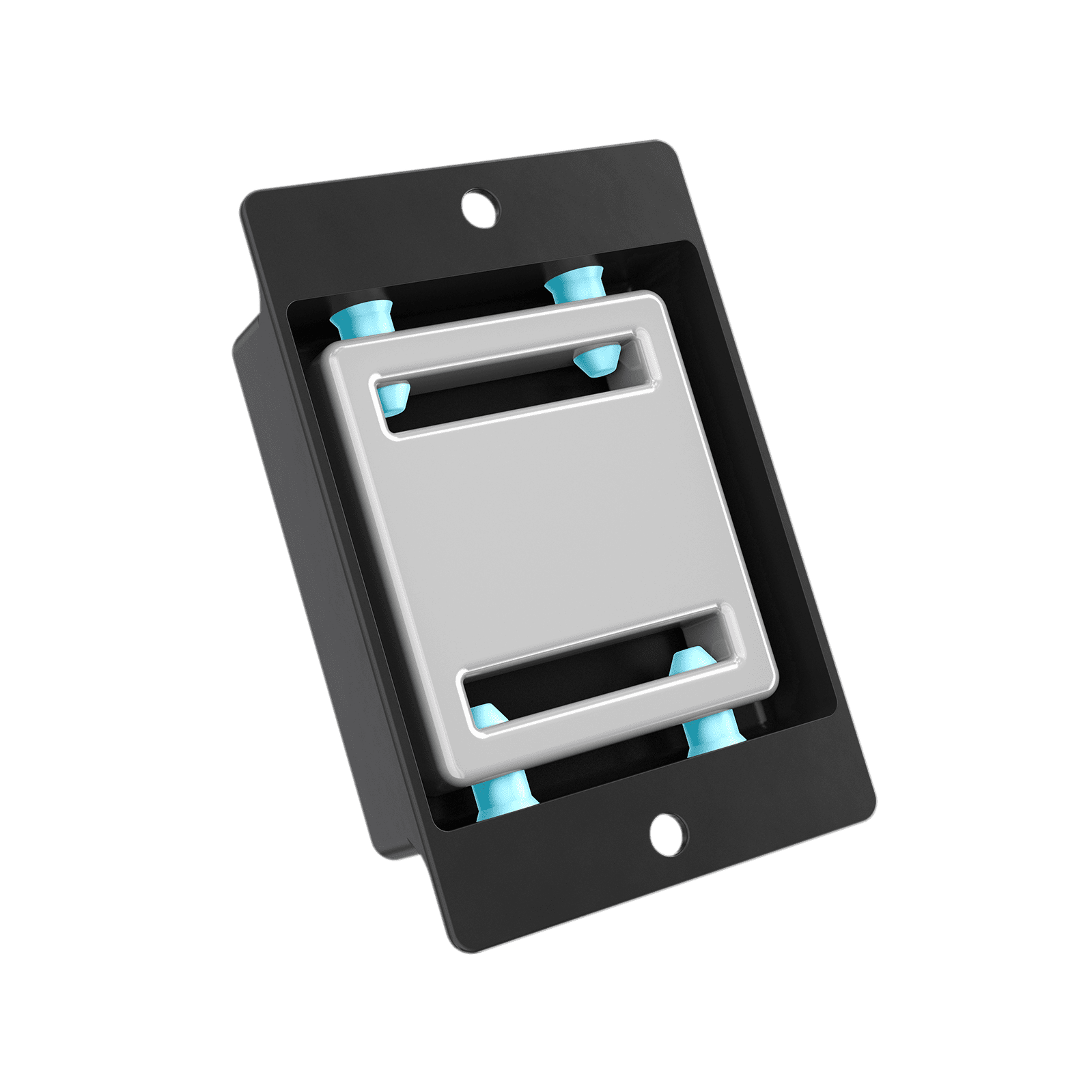

System know-how for best integration into vehicle architecture

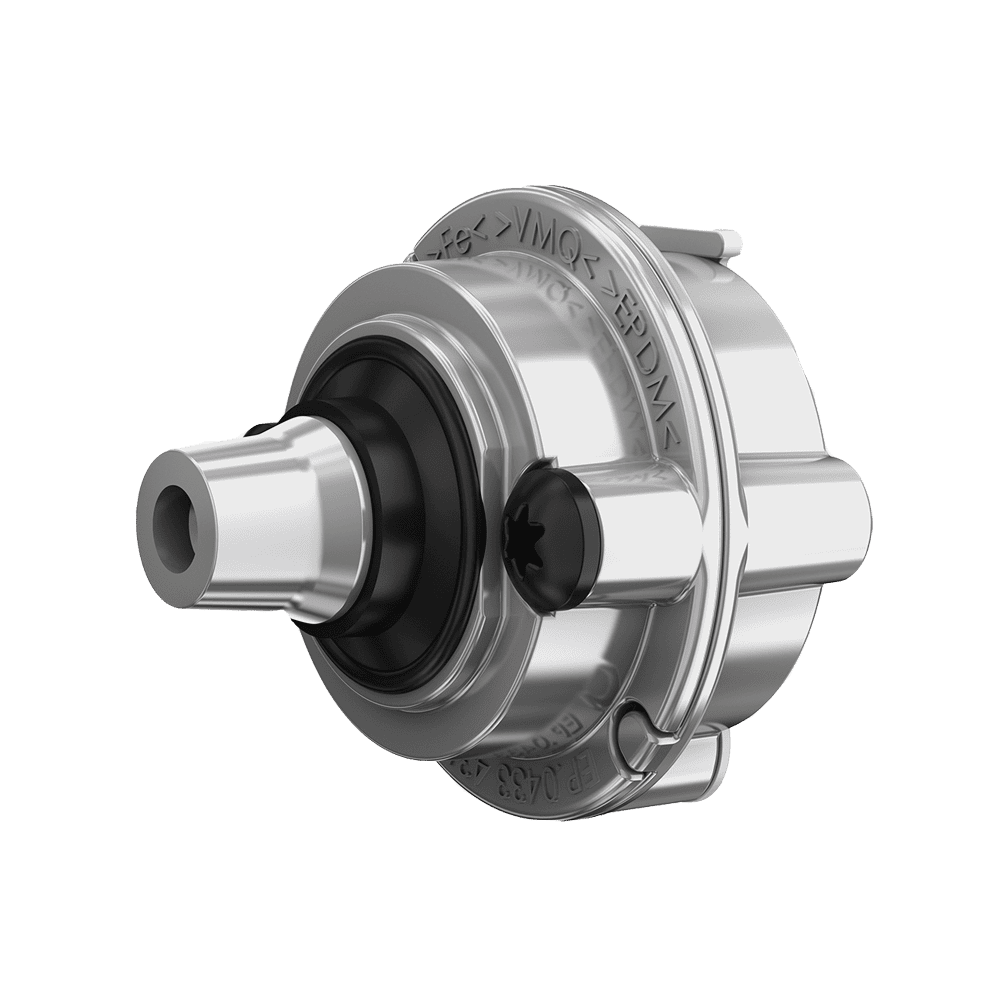

Single and dual layer isolation concepts possible

Cooling systems are used by battery-electric vehicles (BEVs) and plug-in hybrid electric vehicles (PHEVs) to manage cabin temperature and ensure batteries remain within their optimum operating temperature range. They typically rely on electrically driven compressors known as eCompressors to circulate the coolant. The substantial power requirements of fast charging mean that eCompressors experience much greater loads and generate more NVH than their conventional combustion-engine counterparts.

In addition, the NVH that is generated by a vehicle’s electric powertrain motor and its eCompressor occur at very different speed ranges, orders and excitation directions, making a viable solution significantly more complex.

With extensive testing and simulation processes of the entire mounting system, we were able to design, develop and manufacture a bracket and mounting assembly that eliminated internal noise and vibrations during motion, as well as minimizing compressor noise while stationary during fast charging. We developed the capacity to individually select materials depending on application and tailor isolator components for specific requirements, including weight-reduction and cost-optimization. With our comprehensive NVH expertise, we were able to systematically analyze, evaluate and ultimately resolve the described conflicts of objectives.

Particular emphasis was placed on front-wheel and all-wheel drive models, where movement of the eCompressor can be intensified by the electronic drive unit (EDU) leading to higher loads. For rear-wheel drive vehicles, the eCompressor is often mounted to an axle carrier or similar and can use double isolation since the decoupling level of engine mounts is not used.