Darmstadt, 11. April 2019 |

BENTELER and Vibracoustic enter into strategic partnership

Partnership of BENTELER and Vibracoustic combines the competencies of both companies in the development of solutions for electromobility. BENTELER provides know-how on chassis and system integration, Vibracoustic its expertise in reducing noise and vibration and the design of chassis and motor mounts. Customers benefit from noise- and vibration-optimized chassis solutions for electric vehicles.

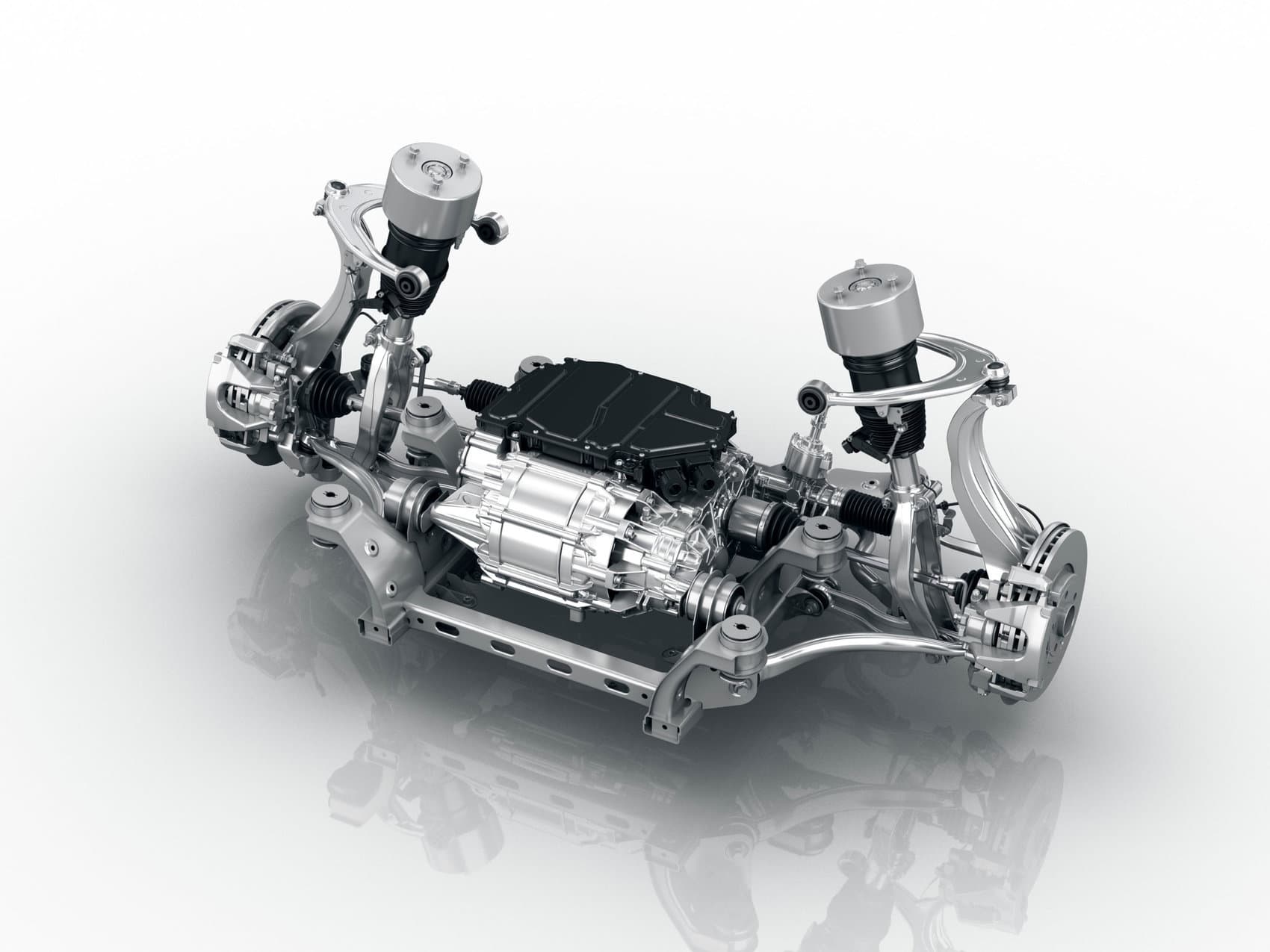

BENTELER and Vibracoustic have entered into a strategic partnership. The cooperation brings together the competencies of both partners in the development of E-Chassis solutions. It enables BENTELER to provide car manufacturers with noise- and vibration-optimized chassis solutions. Car manufacturers can speed up their development cycles as they can rely on a system which is already tuned by Vibracoustic in terms of NVH (Noise, Vibration, Harshness), to support optimum ride and handling. This pre-validated front and rear axle system guarantees customers high functionality and quality in their electric vehicles. In addition, thanks to the partnership, customers benefit from accelerated time-to-market and easy adaptation for a wide range of vehicle classes. They also benefit from less complexity in development and production. At the Shanghai Auto Show, which takes place from 16-25 April, BENTELER and Vibracoustic will showcase their partnership. Electrification in the automotive industry is continuously progressing, driven by megatrends like sustainability, emission reductions as well as new mobility concepts. Car manufacturers have to speed up their development times. As a result they are increasingly seeking pre-validated system solutions that offer an easy and reliable way to build a new electric vehicle from scratch.

Partnerships enable tailor-made customer solutions

“To develop our e-mobility solutions according to the customers’ needs, we use an agile, collaborative network approach with strategic partners like Vibracoustic,” says Marco Kollmeier, Vice President Business Unit Electro-Mobility at BENTELER Automotive. “Thus we are able to provide customers with modular and tailor-made e-mobility solutions.” Frank Mueller, CEO of Vibracoustic, adds: “Comfort is crucial to the overall driving experience and therefore the partnership between BENTELER and Vibracoustic is a perfect fit. With our combined competencies, we can offer customers a pre-validated front and rear axle system which is already tuned for great driving comfort and handling.”

Combined technological competence

BENTELER brings in extensive experience in the development and manufacturing of chassis and structural parts. Based on its know-how on the merging of components and subsystems, BENTELER acts as the system integrator. Vibracoustic contributes its know-how in the field of NVH (Noise, Vibration, Harshness) characteristics. Vibracoustic is developing all the NVH components integrated into the E-Chassis including bushings, subframe mounts, top mounts, motor mounts and micro cellular urethane components. As a pure automotive NVH expert, Vibracoustic also provides its air springs expertise. The company’s know-how about the optimal calibration of the NVH characteristics in electric vehicles complements BENTELER’s competence in chassis solutions.

About Vibracoustic

Vibracoustic is a leading global automotive NVH expert, providing customized solutions adding comfort and supporting efficiency, safety and durability. Its expertise along the entire product life cycle and all vehicle systems as well as its broad product range enable Vibracoustic to solve current and future NVH challenges across all automotive segments. With more than 10,000 employees at 43 production and engineering locations across 19 countries, Vibracoustic serves all major automotive manufacturers. In 2018 Vibracoustic recorded total sales of € 2.1 billion. For more information, see www.vibracoustic.com

About BENTELER

BENTELER is a global, family-owned company serving customers in automotive technology, the energy sector and mechanical engineering. As a strategically innovative partner, we design, produce and distribute safety-relevant products, systems and services. Our portfolio encompasses components and modules for the automotive industry, in the areas of chassis, body, engine and exhaust systems as well as system solutions for electric vehicles. We develop technical equipment and plant for leading automotive suppliers and for the glass-processing industry. Also, based on more than 140 years of experience in steel, we develop seamless and welded quality steel tubes – from material development to tube applications, global distribution of tubes and the associated services.

Under the management of the strategic holding BENTELER International AG, headquartered in Salzburg, Austria, our around 30,000 employees at 141 locations in 38 countries offer first-class manufacturing and distribution competence – all dedicated to delivering a first-class service wherever our customers need us. In the 2018 financial year, Group revenues were €8.072 billion.

BENTELER. The family of driven professionals. Since 1876.

www.benteler.com